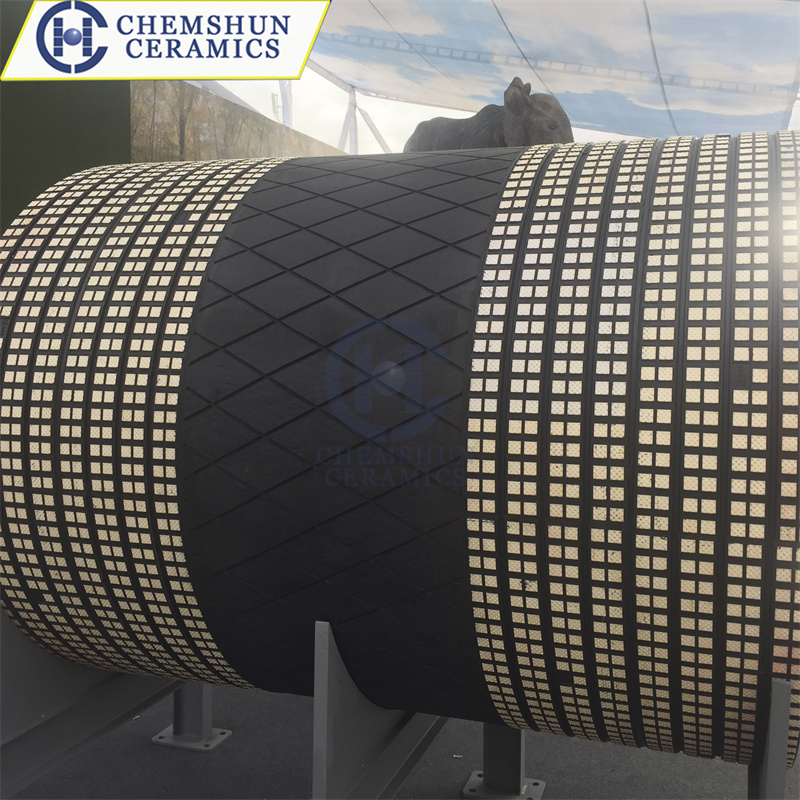

Good Quality Rubber Ceramic Wear Liner Manufacturer - Wear Resistant Ceramic Lined Pulley Lagging – Chemshun

Good Quality Rubber Ceramic Wear Liner Manufacturer - Wear Resistant Ceramic Lined Pulley Lagging – Chemshun Detail:

Feature

Excellent corrosion resistance property

Easily handled size and weight

Excellent heat resistance property

Excellent impact resistance property

Fast and safe installation

Lower production and maintenance cost

Chemshun Ceramic Advantages

Professional technical team to afford CAD designs

Professional installation team to afford install service

Well established process as per international standards

Accept the standard and pre-engineered tiles

Technical Data Sheet

| S.No. | Attributes | Unit | CHEMSHUN 92 I | CHEMSHUN92 II | CHEMSHUN 95 | CHEMSHUN ZTA |

| 1 | Alumina Content | % | 92 | 92 | 95 | 70-75 |

| ZrO2 | % | 25-30 | ||||

| 2 | Density | g/cc | ≥3.60 | ≥3.60 | >3.65 | ≥4.2 |

| 3 | Color | - | White | White | White | White |

| 4 | Water Absorption | % | <0.01 | <0.01 | 0 | 0 |

| 5 | Flexural Strength | Mpa | 270 | 300 | 320 | 680 |

| 6 | Moh’s Density | Grade | 9 | 9 | 9 | 9 |

| 7 | Rock Well Hardness | HRA | 80 | 85 | 87 | 90 |

| 8 | Vickers Hardness(HV5) | Kg/mm2 | 1000 | 1150 | 1200 | 1300 |

| 9 | Fracture Toughness (Min) | MPa.m1/2 | 1000 | 3-4 | 3-4 | 4-5 |

| 10 | Compressive strength | Mpa | 850 | 850 | 870 | 1500 |

| 11 | Thermal Expansion Coefficient (25-1000ºC) |

1×10-6/ºC | 8 | 7.6 | 8.1 | 8.3 |

| 12 | Maximum operation temperature | ºC | 1450 | 1450 | 1500 | 1500 |

Dimension

| Product | Length (mm) |

Width (mm) |

Thickness including Dimple(mm) |

| Ceramic Tile with 5dimples | 20±0.3 | 20±0.3 | 5/6/7/8/9/10 |

| Ceramic Tile with 13dimples | 20±0.3 | 20±0.3 | 5/6/7/8/9/10 |

| Ceramic Tile with 18dimples | 20±0.3 | 30±0.5 | 5/6/7/8/9/10 |

| Ceramic Tile with 13dimples | 25±0.4 | 25±0.4 | 5/6/7/8/9/10 |

| Hex.Tile | 12 | 3/6/10/11/12/20/24/25 | |

| Hex Tile | 19 | 5~25 | |

| Hex Tile | 6 | 3~6 | |

| Square Tile | 20 | 20 | 2~10 |

| Square Tile | 17.5 | 17.5 | 2~10 |

Application in Industries

| Industry | Equipment system | Equipment parts |

| Cement | Pre-blending system for crashing limestone and crude fuel | Chute, bunker, pulley lagging, discharge cone |

| Raw mill system | Feed chute, retaining ring, scraper plate, seal ring, pipeline, bucket guard, cyclone, powder concentrator body, bunker | |

| Cement mill system | Chute, bunker, fan vane wheel, fan casing, cyclone, circular duct, conveyer | |

| Ball mill system | Pulverizer exhauster’s body and vane wheel, powder concentrator’s body, pulverized coal’s pipeline, hot air duct | |

| Sintering system | Inlet/outlet bend, wind value plate, cyclone, chute, dust collector’s pipe | |

| Afterheat system | Separator’s pipeline and wall | |

| Steel | Raw material feeding system | Hopper, silo |

| Batching system | Mixing bunker, mixing barrel, mixing disk, disk pelletizer | |

| Sintered material transport system | Hopper, silo | |

| Dedusting and Ash discharge system | Dedusting pipeline, bend, y-piece | |

| Coking system | Coke hopper | |

| Medium-speed mill | Cone, separation buffles, outlet pipe, pulverized coal’s pipeline, burner cone | |

| Ball mill | Classifier, cyclone separator, bend, powder concentrator’s inner shell | |

| Thermal power | Coal handling system | Bucket wheel machine, coal hopper, coal feeder, orifice |

| Ball mill system | Separator’s pipe, elbow and cone, coal mill’s elbow and straight tube | |

| Medium-speed mill | coal mill body, separation buffles, cone, pipeline, elbow | |

| Fall mill | Pulverized coal’s pipeline and elbow | |

| Dedusting system | Dedusting’s pipeline and elbow | |

| Ash discharge system | Fan duster’s shell, pipeline | |

| Port | Transporting material system | Bucket wheel machine’s disk and hopper, transfer point’s hopper, unloader’s hopper, |

| Smelting | Transporting material system | Measuring hopper, coke hopper, vibrating screen’s chute, head valve, Intermediate bin, tail bin |

| Batching system | batch hopper, mixing machine | |

| Burning system | Ash bucket, pump calcine tube, hopper | |

| Dedusting system | Dedusting’s pipeline and elbow | |

| Chemical | Transporting material system | Hopper, silo |

| Dedusting system | Dedusting’s pipeline and elbow | |

| Processing equipment | Vibromill liner | |

| Coal | Coal handling system | Bucket wheel machine, coal hopper, coal feeder |

| Coal washing system | Hydrocyclone | |

| Mining | Transporting material system | Hopper, silo |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

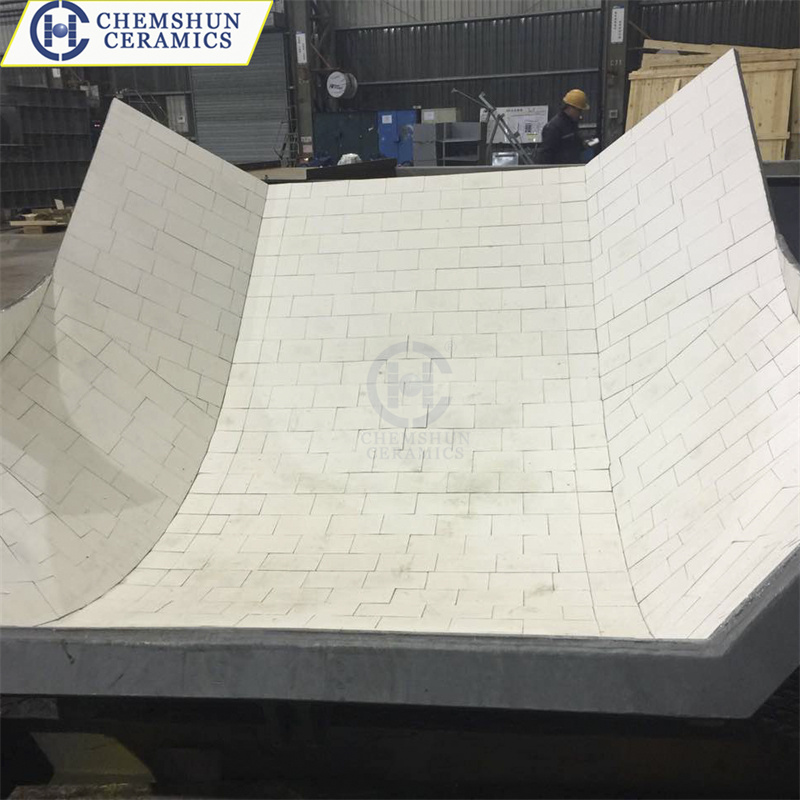

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. High-quality is our life. Consumer need to have is our God for Good Quality Rubber Ceramic Wear Liner Manufacturer - Wear Resistant Ceramic Lined Pulley Lagging – Chemshun , The product will supply to all over the world, such as: Argentina, Canberra, Johor, Our mission is to deliver consistently superior value to our customers and their clients. This commitment permeates everything we do, driving us to continuously develop and improve our products and the processes to fulfill your needs.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!

Write your message here and send it to us