The 99% alumina anti-ballistic ceramic is a high-performance engineering ceramic with α-alumina (α-Al2O₃) as the primary crystalline phase and an alumina content exceeding 98%. Occupying a significant position in personal and vehicle armor protection due to its high hardness, moderate density, excellent wear resistance, and favorable cost-performance ratio. Its protective mechanism primarily relies on its high hardness and modulus to blunt and fragment the incoming projectile, while absorbing and dispersing most of the projectile’s kinetic energy through its own fracture process. The remaining energy is then absorbed by a backing composite material (e.g., ultra-high-molecular-weight polyethylene or unidirectional fabric). Key physical properties include a bulk density of no less than 3.9 g/cm³, a Mohs hardness of 9, a flexural strength up to 580 MPa, coupled with low water absorption (<0.006%) and good thermal stability.

The manufacturing process begins with the selection of high-purity, ultra-fine alumina powders, typically with submicron particle sizes (D50 around 0.35~1.4 μm). Primary forming techniques include dry pressing and isostatic pressing, followed by densification through atmospheric sintering or hot pressing. To overcome the inherent brittleness of the ceramic and improve multi-hit resistance, forefront research focuses on toughening technologies, such as introducing silicon carbide whiskers or zirconia to create alumina matrix composite ceramics. These composite materials can effectively hinder crack propagation at the microstructural level, significantly enhancing toughness, impact resistance, and overall ballistic performance.

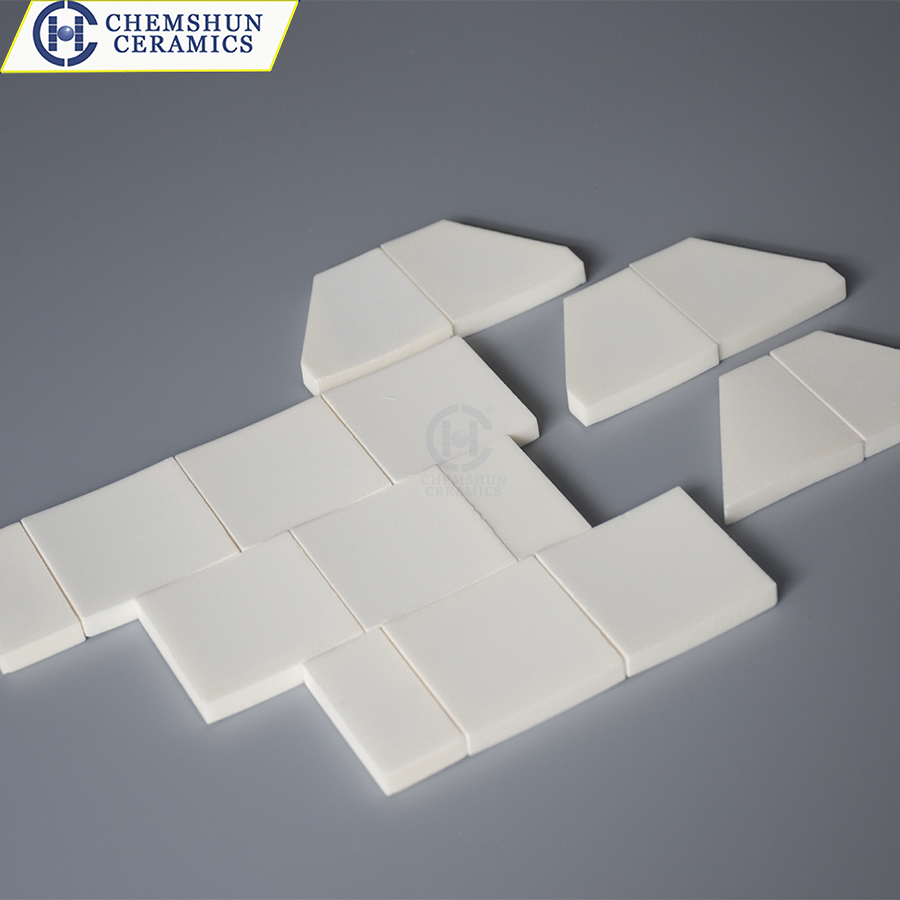

In practical applications, 99% alumina ceramics are often fabricated into regular-shaped tiles (squares, rectangles, hexagons) or curved special-shaped pieces to assemble ergonomic ballistic insert plates. Hard armor plates made from this material have passed professional ballistic tests such as NIJ Standard-0101.06 Level III and IV. Experimental studies have shown that adding confinement to ceramic plates can effectively improve their resistance to penetration. Due to its outstanding bulletproof performance, relatively low weight and competitive cost, 99% alumina bulletproof ceramic has become the dominant material in the ceramic bulletproof plate market.

Post time: Dec-11-2025