In industrial production and various engineering applications, pipelines serve as the key components for material transportation. The performance of pipelines directly affects the operational efficiency and stability of the entire system. Among them, wear resistance is one of the core indicators for evaluating pipeline quality. The emergence of alumina ceramic technology for pipeline linings provides an excellent solution to the problem of pipeline wear, significantly enhancing the wear resistance of the pipelines.

Alumina ceramics, as a high-performance engineering ceramic material, possesses numerous remarkable characteristics. From a chemical perspective, it exhibits extremely high chemical stability, capable of resisting the erosion of various corrosive media such as acids, alkalis, and salts, and maintaining stable performance even in harsh chemical environments. In terms of physical properties, alumina ceramics have extremely high hardness, with a Mohs hardness of up to 9, ranking only after diamond and a few other super-hard materials. This high hardness feature enables it to effectively resist wear when subjected to the scouring of high-speed flowing particles and powders, and is less prone to scratches and flaking.

Placing an alumina ceramic liner inside the pipeline represents a significant innovation in the traditional method of enhancing pipeline wear resistance. While traditional methods such as applying wear-resistant coatings or using ordinary metal liners can improve wear resistance to some extent, they have numerous limitations. Wear-resistant coatings are prone to peeling off over time, resulting in a significant reduction in wear resistance; ordinary metal liners, when subjected to high hardness and high speed of material impact, will also wear out rapidly, requiring frequent replacements, which increases maintenance costs and downtime.

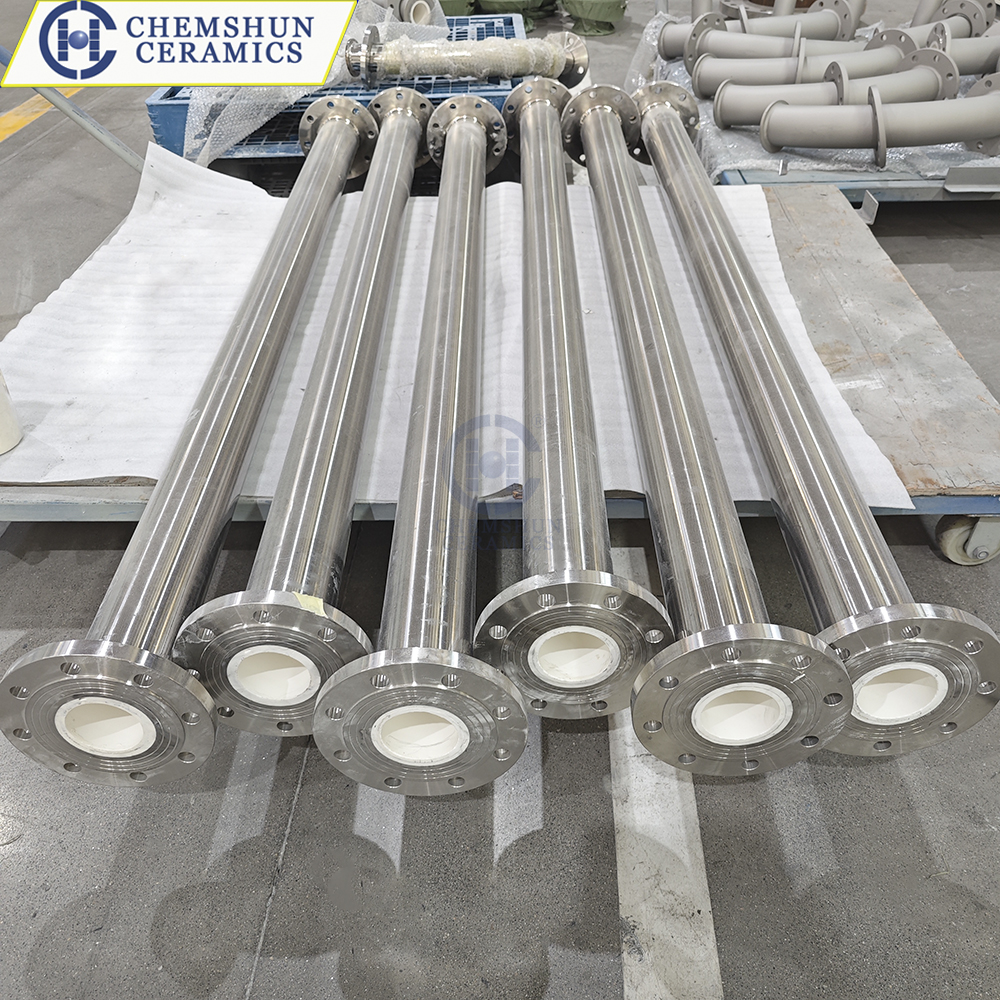

However, the inner lining of the pipe made of alumina ceramic is completely different. Its strong bonding with the pipe’s base material forms a solid and durable wear-resistant layer. In practical applications, whether it is transporting high-hardness materials such as ores and coal, or dealing with fluids containing a large number of sharp particles, the alumina ceramic inner lining pipe can demonstrate outstanding wear resistance. For example, in the material transportation pipelines of mining beneficiation plants, after using the alumina ceramic inner lining, the service life of the pipeline has been extended from the original several months to several years, significantly reducing the frequency of pipeline replacement and lowering production costs.

In addition, the alumina ceramic inner lining pipes also have excellent smoothness, which can reduce the flow resistance of materials in the pipeline, minimize energy loss, and improve the conveying efficiency. At the same time, they are relatively lightweight and will not impose excessive burden on the overall structure of the pipeline, making them easy to install and maintain.

The alumina ceramic lining technology for pipelines has brought a qualitative leap to the field of pipeline wear resistance due to the excellent properties of alumina ceramics. It not only significantly enhances the wear resistance of the pipelines, prolongs their service life, but also reduces maintenance costs and downtime, and improves production efficiency.

Post time: Oct-13-2025