Alumina ceramic is a high-performance industrial material renowned for its Mohs hardness of 9. This property makes it an ideal choice for demanding applications, particularly under conditions of abrasion, corrosion, and high temperatures. This article explores the physical origins of its high hardness and the resulting exceptional performance.

The high hardness of alumina ceramic from its unique crystal structure and chemical bonding. Its primary component, α-alumina (α-Al₂O₃), adopts a corundum structure consisting of closely packed oxygen and aluminum ions bonded by strong ionic and covalent interactions. This bonding confers high lattice energy, enabling the material to resist plastic deformation and fracture under external stress. Moreover, high-purity raw materials and advanced sintering techniques eliminate micro-defects, enhancing overall density and hardness.

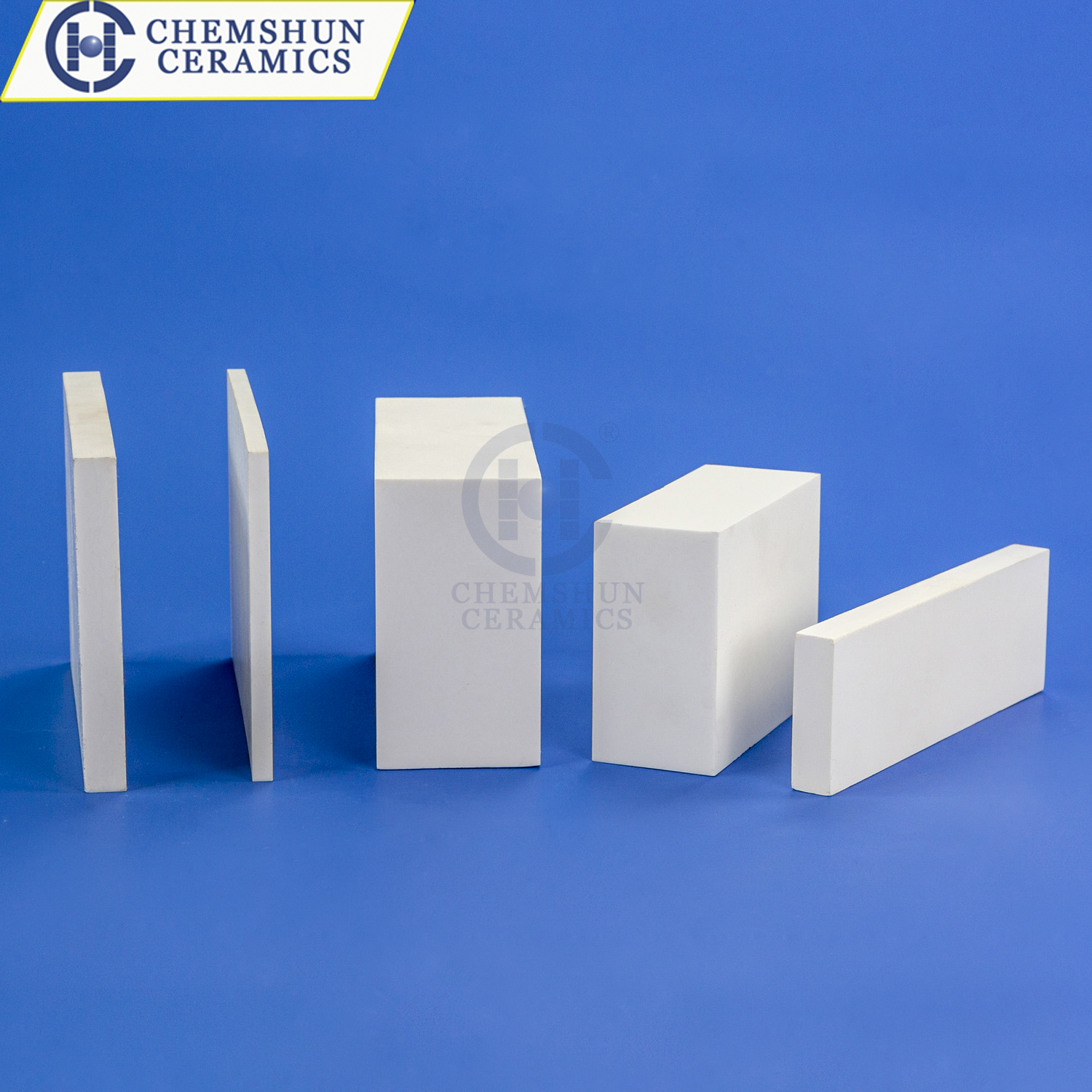

High hardness directly translates to outstanding performance. Its exceptional wear resistance makes it widely applicable in coal handling systems in thermal power plants, sintering and dust removal equipment in steel mills, ore conveying pipelines in mining, raw meal and clinker grinding systems in cement plants, and powder conveying equipment in the chemical industry, outperforming traditional metals in service life. Additionally, the material exhibits excellent chemical corrosion resistance, withstanding strong acids, alkalis, and organic solvents. Under high temperatures, alumina ceramic maintains stable mechanical and chemical properties, operating reliably above 1600°C. Furthermore, high hardness contributes to excellent electrical insulation and low thermal conductivity, making it suitable for electronic devices and thermal management components.

In summary, alumina ceramic, with its Mohs hardness of 9, plays an irreplaceable role in industrial and technological fields. Its superior wear and corrosion resistance, high-temperature stability, and electrical insulation properties make it a critical material for advanced manufacturing and innovative technologies. As processing techniques continue to evolve, the application prospects of alumina ceramic are expected to expand further.

Post time: Oct-28-2025