In industrial production, pipelines play a role in transporting materials. When transporting materials with high hardness, high corrosiveness or high flow rate, the problem of pipeline wear often becomes a major challenge for enterprises. Traditional pipes, due to their insufficient wear resistance, often need to be replaced frequently, which not only increases costs but may also lead to production disruptions. To effectively solve this problem, alumina ceramic-lined pipes can be chosen. Their excellent wear resistance can significantly increase the service life of the pipes and bring remarkable benefits to industrial production.

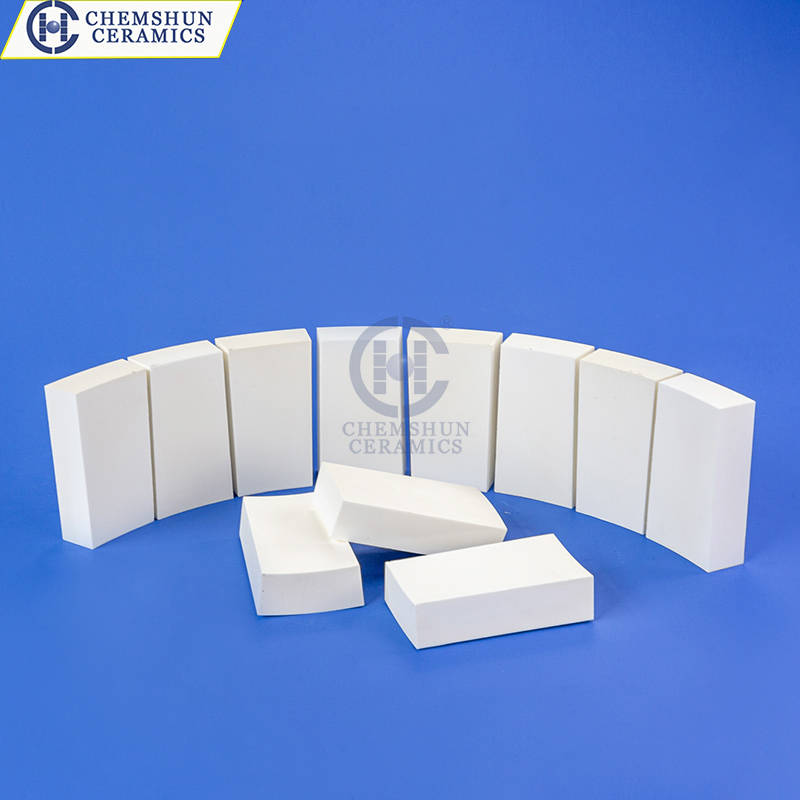

Alumina ceramics are inorganic non-metallic materials mainly composed of alumina (Al2O3), featuring extremely high hardness, wear resistance and corrosion resistance. They are ideal materials for solving pipeline wear problems.

1. Excellent wear resistance

The hardness of alumina ceramics is second only to that of diamond, with a Mohs hardness of up to 9, which is much higher than that of ordinary steel (with a Mohs hardness of approximately 5.5 to 6.5). Its wear resistance is dozens or even hundreds of times that of ordinary steel, and it can effectively resist the erosion and wear of materials. Under the same working conditions, the service life of the alumina ceramic-lined pipe is 5 to 10 times longer than that of the traditional pipe, significantly reducing the frequency of pipe replacement.

2. Good corrosion resistance

Alumina ceramics have excellent chemical stability and can resist the erosion of various corrosive media such as acids, alkalis and salts. In industries such as chemical engineering and pharmaceuticals, when transporting corrosive media, alumina ceramic-lined pipes can operate stably for a long time, avoiding leakage and pollution problems caused by pipe corrosion.

3. High-temperature resistance

Alumina ceramics have a relatively high melting point (approximately 2050℃) and excellent high-temperature resistance, enabling them to be used for a long time in high-temperature environments without deformation or failure. In industries such as power and metallurgy, when transporting high-temperature materials, alumina ceramic-lined pipes can withstand the test of high temperatures, ensuring the continuity of production.

4. Smooth surface

The inner lining surface of the alumina ceramic pipe is smooth and has a low roughness, which can reduce the flow resistance of materials in the pipe and lower energy consumption. Meanwhile, the smooth surface is also less likely to adhere to materials, reducing the risk of blockage inside the pipeline.

Alumina ceramic-lined pipes, with their outstanding wear resistance, corrosion resistance, high-temperature resistance and smooth surface, have become an efficient solution to the problem of pipe wear. It can significantly increase the service life of pipelines, reduce maintenance costs, enhance production efficiency, and ensure the stability and economy of industrial production. With the continuous development of industrial technology, the requirements for pipeline performance are getting higher and higher. Alumina ceramic-lined pipes will be widely used in more industries and fields.

Post time: May-28-2025