In the material handling stage of industrial production, silos and hoppers, as key equipment for material storage and transportation, have an operational status that directly impacts the efficiency and stability of the entire production process. However, the frequent flow and friction of materials within silos and hoppers make the inner walls of the equipment highly susceptible to wear. This not only shortens the service life of the equipment and increases maintenance costs but may also lead to production interruptions due to equipment failure, resulting in significant economic losses for enterprises.

Alumina ceramic, as an advanced functional ceramic material, possesses exceptional hardness and outstanding wear resistance. With a hardness rating of HRA85 or higher, it is second only to ultra-hard materials such as diamond and cubic boron nitride, and significantly surpasses the hardness of ordinary metallic materials. This high hardness enables alumina ceramic linings to maintain surface integrity when subjected to intense scouring and abrasion from various materials, making them highly resistant to wear.

In practical applications, whether facing ores and coal containing sharp particles or corrosive chemical raw materials, alumina ceramic linings demonstrate exceptional wear resistance. Compared to traditional metal linings, the service life of alumina ceramic linings can be extended by several times to tens of times. For example, in the ore processing plant silos of a mining company, the originally used metal linings required replacement every 3 to 6 months on average. After switching to alumina ceramic linings, the service life was extended to 2 to 3 years, significantly reducing equipment maintenance frequency and costs.

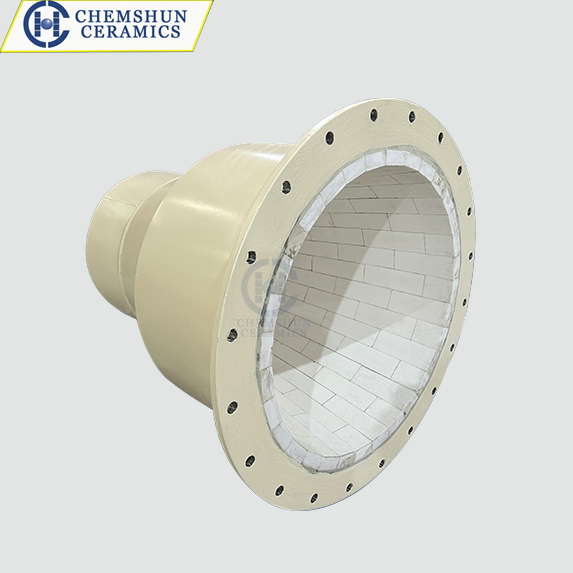

Alumina ceramic linings can be custom fabricated to match the actual dimensions and shape of silos and hoppers, allowing for easy and quick installation. In terms of maintenance, only regular inspections for wear are required, with partial replacements performed when necessary. This results in low maintenance costs and straightforward operations.

Post time: Oct-22-2025