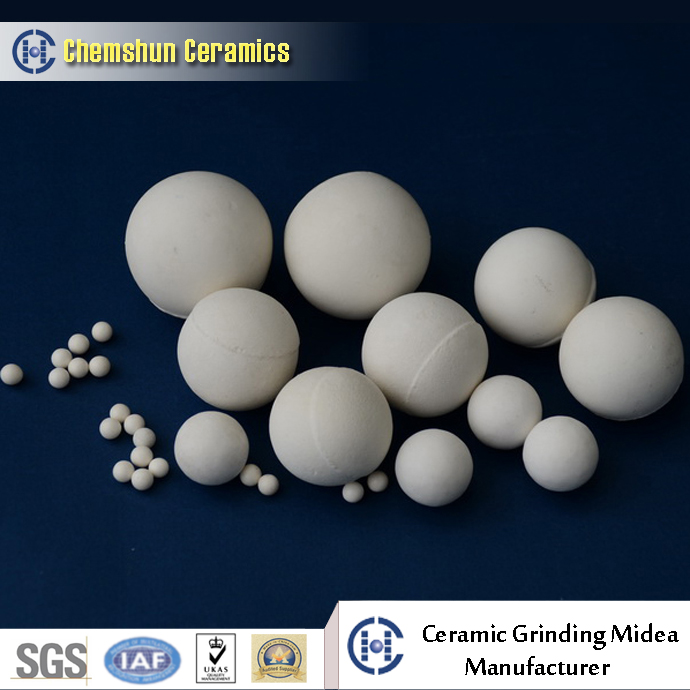

92% alumina ceramic grinding balls are mainly made of alumina powder, supplemented with a small amount of metal oxides, and then formed through high-temperature sintering. They are spherical in shape and come in a wide range of sizes, with common diameters ranging from 0.5 mm to 10 cm. This product features high hardness, excellent wear resistance, superior chemical corrosion resistance, and moderate mechanical strength. Its density typically falls between 3.6 and 3.7 g/cm³, and its Mohs hardness can reach up to 9. Due to its stable crystal structure, it maintains a low attrition rate during long-term grinding processes, preventing contamination of the ground materials.

Alumina ceramic grinding balls are widely used in ball milling processes in industries such as coatings, building materials, chemicals, and ceramics. During the preparation of ceramic glazes, they can effectively reduce the particle size of the materials and prevent iron contamination; in the cement industry, they are used for grinding slag and clinker; in the production of electronic ceramics and magnetic materials, their high purity and stability ensure the quality of the ground powder materials. Moreover, in the wet grinding of dyes, pigments, and positive and negative electrodes of lithium batteries, because alumina ceramic grinding balls have excellent acid and alkali resistance, they can become the key grinding medium.

Selecting high-quality 92% alumina ceramic grinding balls requires comprehensive consideration of multiple technical indicators. Firstly, the actual content of alumina and the volume density should be tested to ensure they meet the 92% composition standard and the theoretical density range. Secondly, the wear resistance should be evaluated through wear tests, usually using the wear rate per unit time or the grams of material lost per ton of grinding as quantitative indicators. Additionally, the surface smoothness and roundness should be observed to avoid cracks, pores, or shape deviations.

Post time: Sep-16-2025