In industrial fields such as mining, power, cement, and metallurgy, the inner walls of equipment are constantly subjected to the fierce erosion and wear caused by high-speed material flows. This wear not only leads to frequent equipment shutdowns for maintenance, incurring high costs, but also may cause unexpected shutdowns or even safety accidents. How can equipment effectively resist the invasion of wear? Wear-resistant alumina ceramic tiles, with their outstanding performance, have become the ideal solution in the field of industrial anti-wear.

Core Defense: The Outstanding Performance of Aluminum Oxide Ceramics

The core material of wear-resistant ceramic tiles is high-purity aluminum oxide (Al₂O₃), which is sintered at high temperatures to form a dense and high-hardness ceramic structure, endowing it with unparalleled wear resistance. Its Mohs hardness is as high as 9 (second only to diamond), far exceeding that of ordinary steel, easily resisting the scratching and cutting of hard materials such as quartz sand, ores, and coal powder. Moreover, it has excellent wear resistance and corrosion resistance, significantly extending the service life of equipment. The surface of wear-resistant ceramic plates is smooth, reducing the flow resistance of materials, minimizing frictional heat generation and energy consumption, and effectively preventing material adhesion and blockage.

Wear-resistant ceramic tiles are almost applicable to all industrial equipment that is subject to material abrasion and wear:

Material conveying systems: coal/powder/ash pipelines, coal drop pipes, chutes, hoppers, valve linings, etc.

Powder processing equipment: inlet and outlet flue ducts of dust collectors, cyclone separators, inner walls of powder classifiers, elbow joints of pneumatic conveying systems, etc.

Energy and power equipment: coal mill outlets, coarse and fine powder separators, primary air ducts, volute casings of powder feeders, boiler soot blower areas, ash and slag systems, etc.

Mining and metallurgical equipment: ore crushing/separation/conveying equipment, magnetic separator tanks, tailings pipelines, sintering equipment, etc.

Cement production equipment: raw material/fly ash/coal powder conveying pipelines, classifiers, V-type classifiers, preheater cones, side walls of cooler machines, etc.

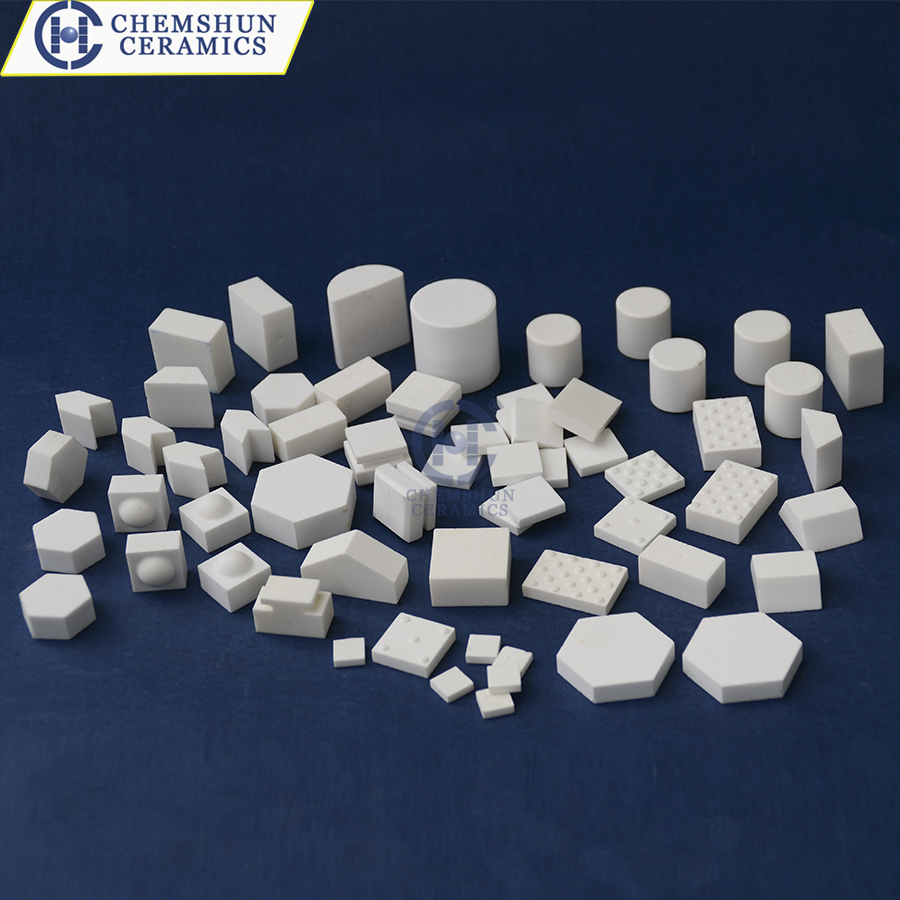

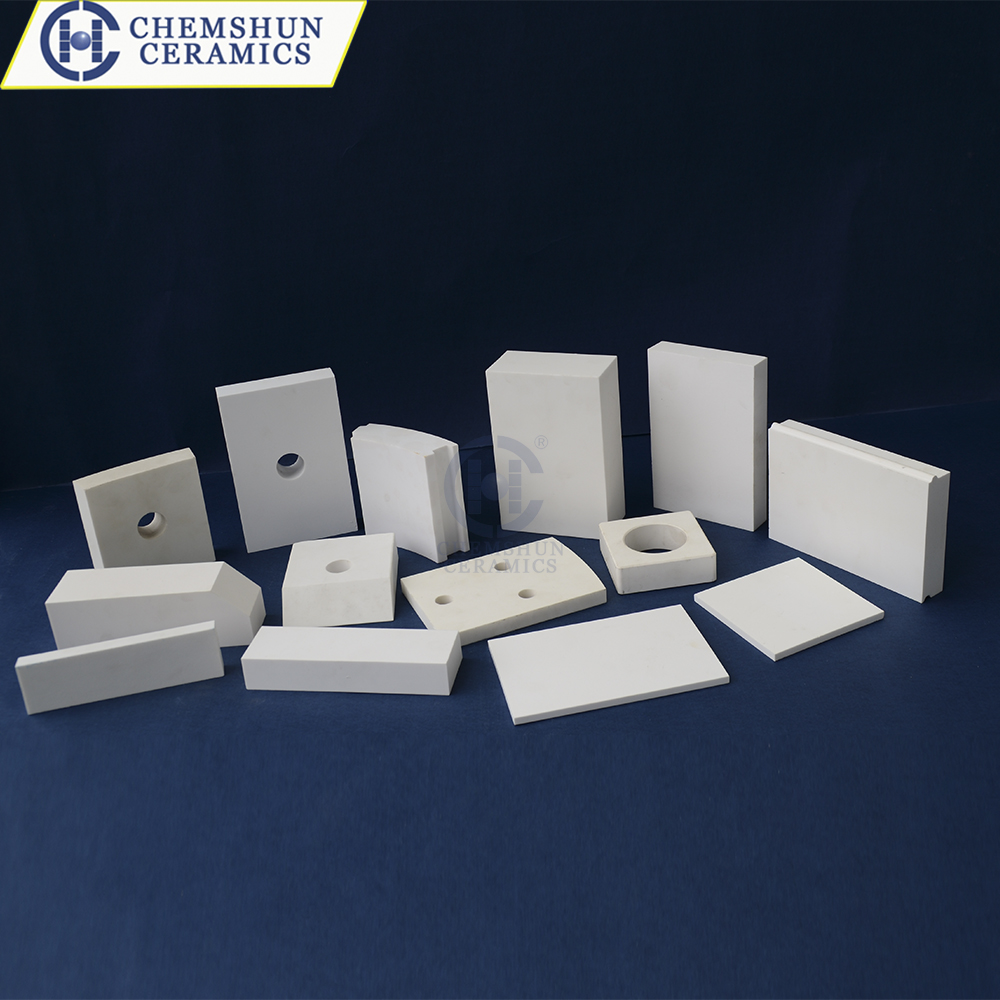

Wear-resistant alumina ceramic tiles, like custom-made “armor guards” for equipment, with their outstanding hardness, wear resistance and diverse shapes (square, hexagonal, circular), build a solid defense line for the inner walls of industrial equipment.

Post time: Jul-26-2025