As an important part of the field of industrial wear protection, the high temperature resistance of wear-resistant ceramics has always been one of the focuses of everyone’s attention. Especially in some working conditions with large temperature changes or high ambient temperature, choosing the correct type of wear-resistant ceramics and the correct installation method are of great significance for safe production and energy saving and high efficiency. So what are the main factors affecting the high temperature resistance of wear-resistant ceramics?

1. Material purity of wear-resistant ceramics: The wear-resistant ceramics we often talk about mostly refer to alumina wear-resistant ceramics, and the purity of alumina has a direct impact on the high temperature resistance of wear-resistant ceramics. Alumina wear-resistant ceramics are sintered at a high temperature of 1700°C and have excellent high temperature resistance. However, in practical applications, if the purity of alumina is not high, ceramics will contain other elements. These materials will show different thermal expansion and contraction properties at high temperatures or sudden cooling and heating due to different properties. This situation is not obvious when the temperature changes slowly or the range of change is small, but when the temperature changes drastically or encounters a high temperature of 800, 900 or even 1,000 degrees, this change will have a great impact, and ceramics with higher purity need to be selected.

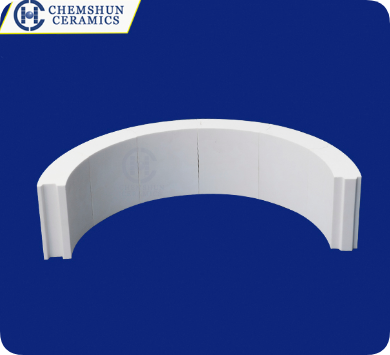

2. Installation method: The installation method of wear-resistant ceramics also has a direct impact on the high temperature resistance of ceramics. For example, when ordinary ceramic adhesive is used to paste ceramics, the high temperature range it can withstand is about 150°C. High-temperature adhesive can increase this temperature to 200°C, but once the temperature resistance range of the adhesive is exceeded, the viscosity of the adhesive will be affected, which can easily cause the ceramic to fall off. Compared with the pasting method, the ceramics installed by the stud welding method and the dovetail slot can withstand a high temperature of 750°C. The integrally formed wear-resistant ceramic pipe can greatly weaken the limitation of the installation method on the temperature resistance of ceramics.

3. Materials composited with ceramics: Ceramics are often used in combination with other materials, such as metals, rubber, etc. In this case, when judging the high temperature resistance of wear-resistant ceramics, we must consider the temperature resistance of the composite material. For example, ceramic-rubber composite materials are not suitable for use in high temperature conditions.

In summary, there are three main factors that affect the high temperature resistance of wear-resistant ceramics, so these factors need to be considered comprehensively when choosing wear-resistant ceramics.

Post time: Apr-26-2025