During the operation of thermal power plants, equipment wear and tear has always been an important issue affecting production efficiency and increasing maintenance costs. The belt conveyor rollers and coal drop pipes of the coal conveying system, as well as the economizers and superheaters of the boiler system, are subject to long-term erosion by materials and high-temperature corrosion, resulting in extremely severe wear. In recent years, alumina ceramic tiles have been widely used in the field of anti-wear in power plants due to their outstanding performance, achieving remarkable anti-wear effects and effectively solving this problem.

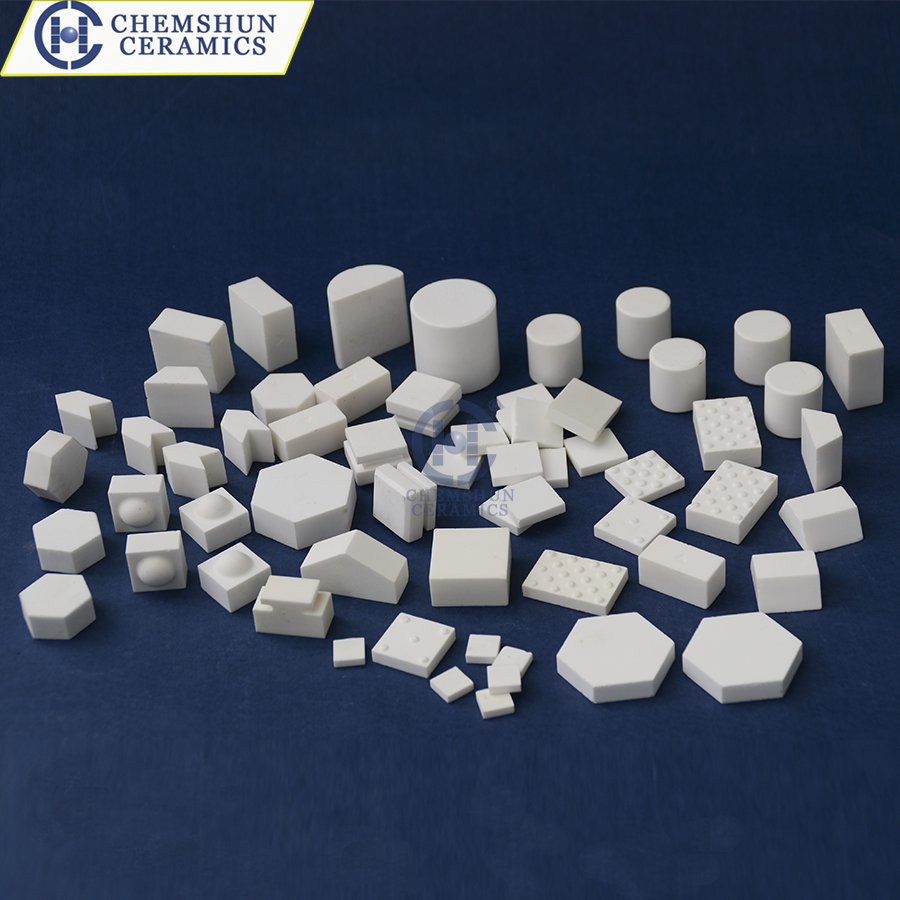

The excellent anti-wear performance of alumina ceramic tiles stems from their unique material properties. Alumina ceramics have extremely high hardness, with a Mohs hardness of up to 9, second only to diamond, and can resist the strong erosion of material particles. Meanwhile, it also has excellent wear resistance. Its wear resistance is 266 times that of manganese steel and 171.5 times that of high-chromium cast iron, which can significantly extend the service life of equipment. In addition, alumina ceramic tiles also have excellent high-temperature resistance and can operate stably in a high-temperature environment of 1200℃, which makes them perform outstandingly in anti-wear applications for high-temperature equipment in power plants.

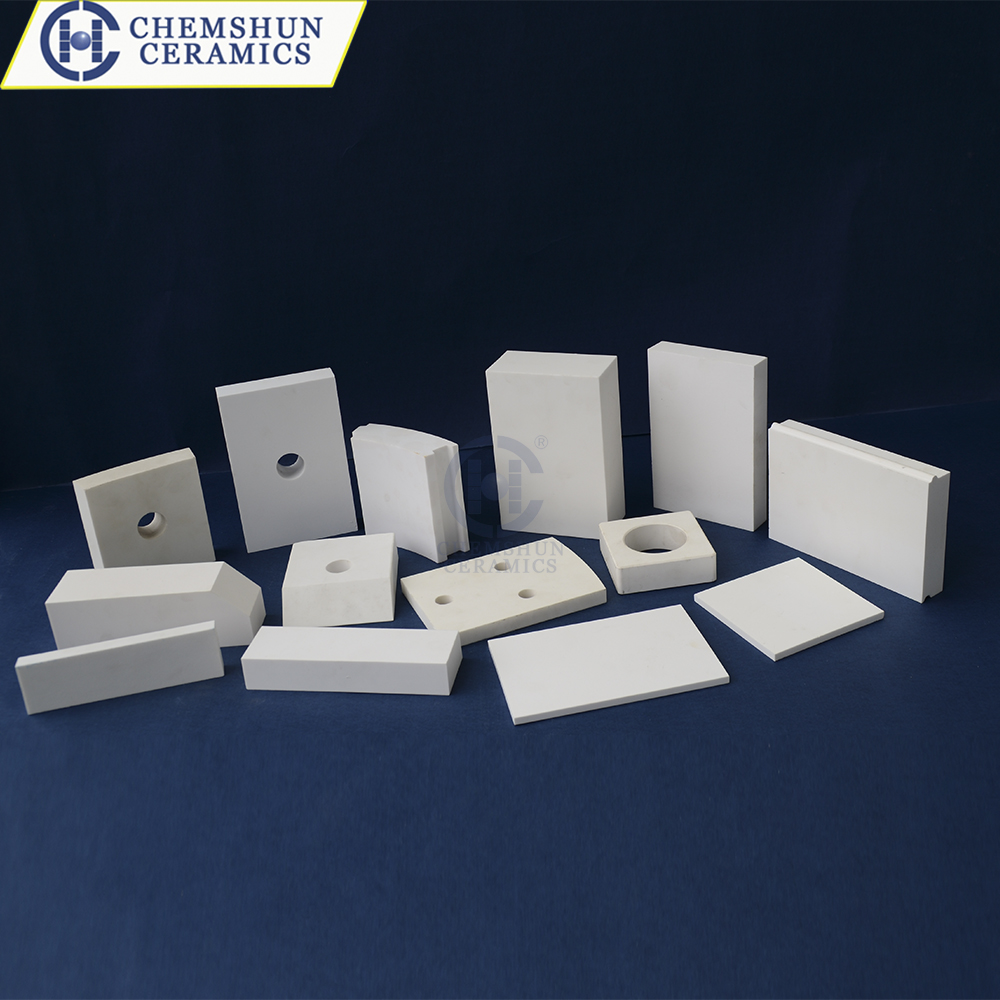

In the practical application of power plants, the installation methods of alumina ceramic sheets are flexible and diverse. The common ones include adhesive type, inlay type and welding type. Adhesive installation is to firmly adhere ceramic sheets to the surface of the equipment through special high-temperature resistant and high-strength adhesives. This method is easy to operate and suitable for components with complex shapes. The inlaid installation involves processing grooves on the surface of the equipment that match the shape of the ceramic sheet and embedding the ceramic sheet into it. This method has a good fixing effect and is suitable for parts that are subject to greater impact forces. Welded installation involves welding ceramic sheets onto the surface of equipment through a special welding process. It features high connection strength and is suitable for areas with severe wear and harsh working conditions.

Take the coal drop pipe of the power plant’s coal conveying system as an example. Before the installation of alumina ceramic plates, due to the continuous erosion of coal particles, the pipe wall of the coal drop pipe was severely worn, and it needed to be replaced on average every six months. This not only increased the maintenance cost but also affected the normal production of the power plant. After adopting the adhesive installation of alumina ceramic plates, the wear resistance of the coal drop pipe has been greatly enhanced, the replacement cycle has been extended to 3 to 5 years, significantly reducing the downtime for maintenance and improving production efficiency.

The application of alumina ceramic tiles in components such as economizers and superheaters of the boiler system has also achieved good anti-wear effects. These components have been exposed to high temperatures and high dust levels for a long time, resulting in prominent wear and corrosion problems. By installing alumina ceramic tiles in an inlaid or welded manner, a solid protective layer is formed, effectively resisting the erosion and corrosion of high-temperature dust, reducing the damage rate of components, and enhancing the stability and safety of boiler operation.

The application of alumina ceramic tiles in power plants not only significantly enhances the anti-wear performance of equipment but also brings considerable economic benefits. Reducing the frequency of equipment maintenance and replacement has lowered maintenance costs and downtime losses. Extending the service life of equipment, enhancing its reliability and operational efficiency, and providing a strong guarantee for the stable production of power plants. With the continuous advancement of technology, the application prospects of alumina ceramic tiles in power plants will be even broader, and they are expected to play an important role in more fields, helping power plants achieve efficient, stable and economic operation.

Post time: May-23-2025