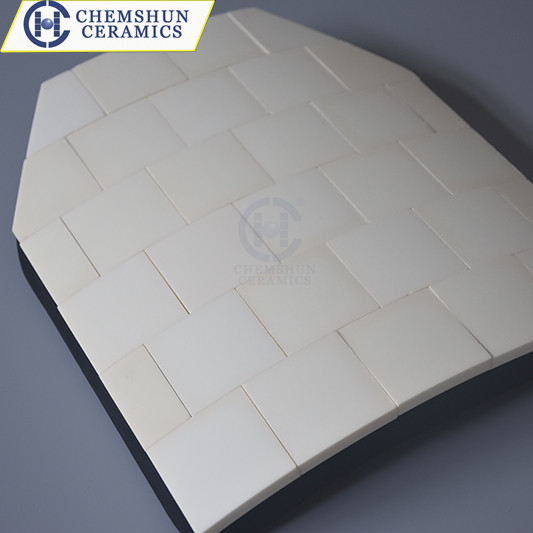

99% alumina ceramics, with their high strength, high hardness and chemical inertness in many environments, can be well applied in the field of bulletproof. Bulletproof ceramics and high-strength and high-modulus fiber composite plates together form the bulletproof layer. When a high-speed bullet collides with the ceramic layer, the ceramic layer shatters or develops cracks that spread outwards from the center point, consuming most of the bullet’s energy. Subsequently, the high-modulus fiber composite plate further consumes the remaining energy of the bullet.

The energy absorption process of bulletproof ceramics can be roughly divided into three stages:

① Initial impact stage: The bullet strikes the ceramic surface, dulling the bullet head and breaking into fine and hard fragments on the ceramic surface.

② Erosion stage: The blunted bullet continues to erode the fragment area, forming a continuous layer of ceramic fragments.

③ Deformation, cracking and fracture stage: Finally, tensile stress is generated in the ceramic, causing it to shatter. During the process of the bullet hitting the ceramic, both the bullet and the ceramic were damaged.

One advantage of bulletproof ceramics over metals is that metal materials undergo plastic deformation and absorb energy when resisting the impact of bullet heads. If worn on the human body, this plastic deformation may cause harm to the human body. Bulletproof ceramics hardly undergo plastic deformation.

Therefore, the application of advanced ceramics in armor systems is highly attractive and has become a widely used protective armor for equipment such as bulletproof vests, vehicles, and aircraft.

Post time: May-12-2025