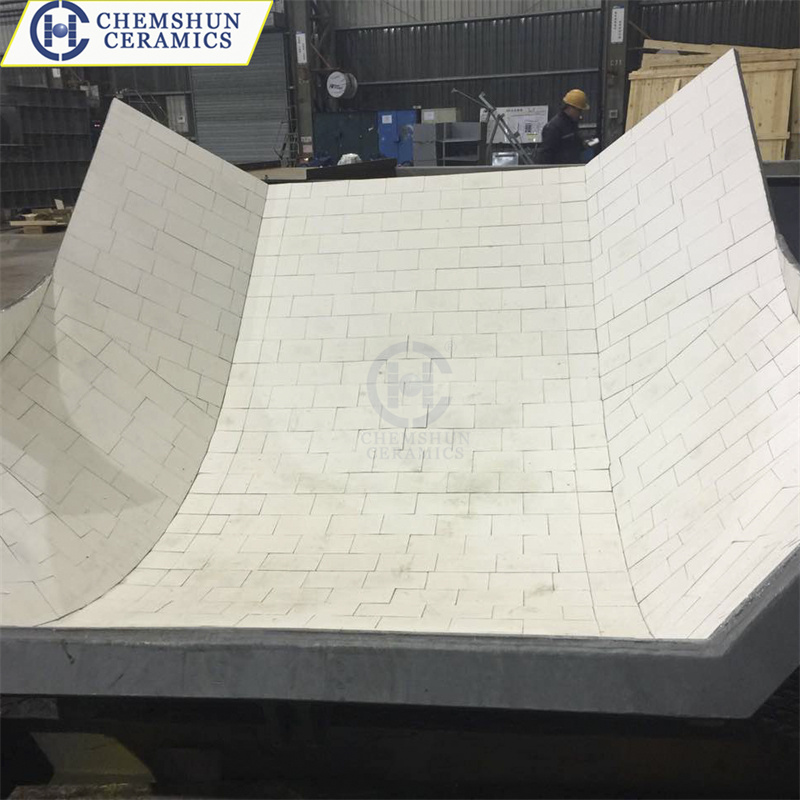

OEM/ODM Factory Dry Grinding Solution - Alumina Ceramic Lined Bunker & Hopper – Chemshun

OEM/ODM Factory Dry Grinding Solution - Alumina Ceramic Lined Bunker & Hopper – Chemshun Detail:

Advantages

Low wear loss and long working life.

Good impact resistance.

Good corrosion resistant

Good thermal shock resistance.

Smooth surface and good adherence resistance.

Quick installation and good service after sale.

Complicated shape and various size designed according to customers’ demands.

Application

-As alumina ceramic wear-resisting lining of coal-electing equipment on coal industry

-Cements industries;

-As wear resistant alumina ceramic lining of fall funnel, lining of wear-resisting pipe and bender,

-As wear resistant alumina ceramic liner of material tranfer pipe and chute, etc, on steel industry.

-As wear ceramic liner for l thansfer equipment;

-As Alumina ceramic wear plates Inside and outside surface of powder separating equipment on iron and steel works;

-Ceramics, mines and other grinding equipment lining;

-Parts of equipment hermal and power plants;

-Grinding systems Mixer Application areas

-Separator systems chain conveyor

-Cyclones diffusor

-sinter slurry ducts

-Hooper High temperature cyclones

-Ventilator housing salt plants

Technical data

| S.No. | Attributes | Unit | CHEMSHUN 92 I | CHEMSHUN92 II | CHEMSHUN 95 |

| 1 | Alumina Content | % | 92 | 92 | 95 |

| 2 | Density | g/cc | ≥3.60 | ≥3.60 | >3.65 |

| 3 | Color | - | White | White | White |

| 4 | Water Absorption | % | <0.01 | <0.01 | 0 |

| 5 | Flexural Strength | Mpa | 270 | 300 | 320 |

| 6 | Moh’s Density | Grade | 9 | 9 | 9 |

| 7 | Rock Well Hardness | HRA | 80 | 85 | 87 |

| 8 | Vickers Hardness(HV5) | Kg/mm2 | 1000 | 1150 | 1200 |

| 9 | Fracture Toughness (Min) | MPa.m1/2 | 1000 | 1150 | 1200 |

| 10 | Compressive strength | Mpa | 850 | 850 | 870 |

| 11 | Thermal Expansion Coefficient | 1×10-6/ºC | 8 | 7.6 | 8.1 |

| (25-1000ºC) | |||||

| 12 | Maximum operation temperature | ºC | 1450 | 1450 | 1500 |

Normal chemshun ceramic tile liner sizes

| Alumina ceramic tile popular Sizes (Length*width*thickness ) |

| 100*100*20mm (4″x4″x3/4″) |

| 150*100*13mm (6″x4″x1/2″) |

| 150*100*15mm (6″x4″x5/8″) |

| 150*100*20mm (6″x4″x3/4″) |

| 150*100*25mm (6″x4″x1″) |

| 150*100*50mm (6″x4″x2″) |

| 150*50*25mm (6″x4″x1″) |

| 100*75*25mm (4″x3″x1″) |

| 120*80*20mm |

| 228*114*25mm |

| 114*114*25mm |

| More sizes and customized size acceptable. Chemshun ceramics afford the relative weldable steel cone and ceramic rod. |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

Product detail pictures:

Related Product Guide:

With our excellent administration, strong technical capability and strict excellent control method, we carry on to offer our clients with responsible good quality, reasonable costs and great companies. We intention at becoming considered one of your most responsible partners and earning your pleasure for OEM/ODM Factory Dry Grinding Solution - Alumina Ceramic Lined Bunker & Hopper – Chemshun , The product will supply to all over the world, such as: Congo, Mongolia, Albania, Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.