Professional China Aluminum Oxide Ceramic - 99.7% Alumina Wafer Polish Plate – Chemshun

Professional China Aluminum Oxide Ceramic - 99.7% Alumina Wafer Polish Plate – Chemshun Detail:

Application

As the Alumina ceramic wafer polishing and sapphire lapping disks used in the semi-conductive, diamond polishing etc.

Process: All types of Polishing and lapping process, such as CMP chemical mechanical polishing, Mechanical Polishing, Precision Polishing.

Feature

High purity and chemical durability

High Mechanical Strength and Hardness

High Corrosion Resistance

High Voltage Resistance

High Temperature Resistant Up to 1700ºC

Extremely Abrasion Resistance Performance

Excellent Insulation Performance

All type of Size 180,360, 450, 600mm etc

| Product name | 99.7 high purity Alumina ceramic Polishing Lapping Discs |

| Material | 99.7% alumina |

| Normal Size | D180, 360, 450, 600mm, customized size accepted. |

| Color | Ivory |

| Application | Wafer and Sapphire CMP process in semi-conductive industry |

| Min.Order | 1Pic |

Chemical / physical Information

| Unit | 99.7 Alumina Ceramics | ||

| General Properties | Al2O3 content | wt% | 99.7-99.9 |

| Density | gm/cc | 3.94-3.97 | |

| Color | - | Ivory | |

| Water absorption | % | 0 | |

| Mechanical Properties | Flexural Strength(MOR) 20 ºC | Mpa(psix10^3) | 440-550 |

| Elastic Modulus 20ºC | GPa (psix10^6) | 375 | |

| Vickers Hardness | Gpa(kg/mm2) R45N | >=17 | |

| Bending Strength | Gpa | 390 | |

| Tensile Strength 25ºC | MPa(psix10^3) | 248 | |

| Fracture Toughness (K I c) | Mpa* m^1/2 | 4-5 | |

| Thermal Properities | Thermal conductivity(20ºC) | W/mk | 30 |

| Coefficient of Thermal expansion(25-1000ºC) | 1x 10^-6/ºC | 7.6 | |

| Thermal Shock Resistance | ºC | 200 | |

| Maximum use temperature | ºC | 1700 | |

| Electrical Properities | Dielectric Strength (1MHz) | ac-kv/mm(ac v/mil) | 8.7 |

| Dielectric Constant(1 MHz) | 25ºC | 9.7 | |

| Volume Resistivity | ohm-cm (25ºC) | >10^14 | |

| ohm-cm (500ºC) | 2×10^12 | ||

| ohm-cm (1000ºC) | 2×10^7 |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

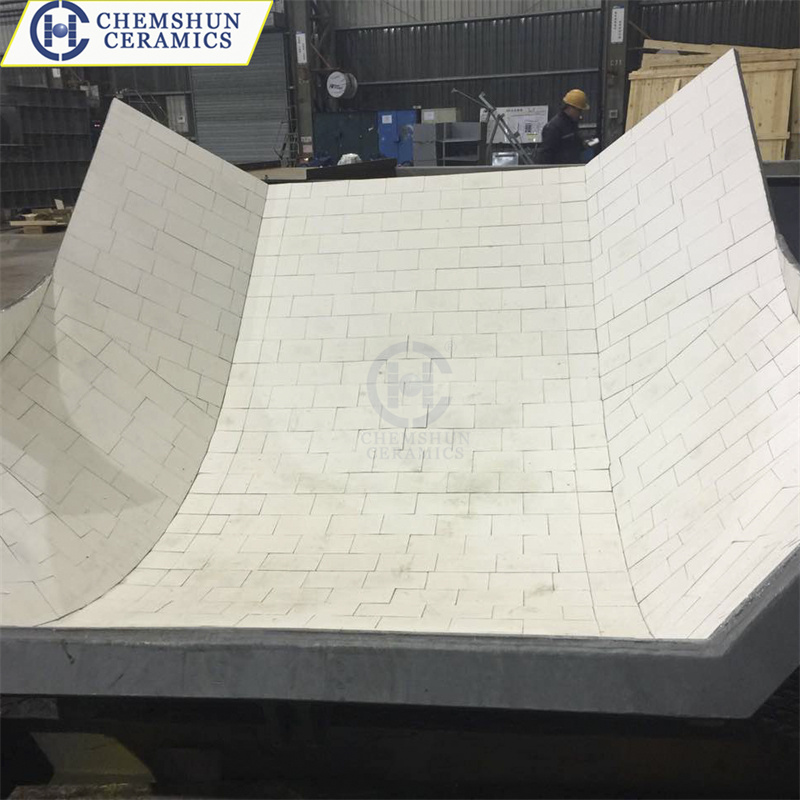

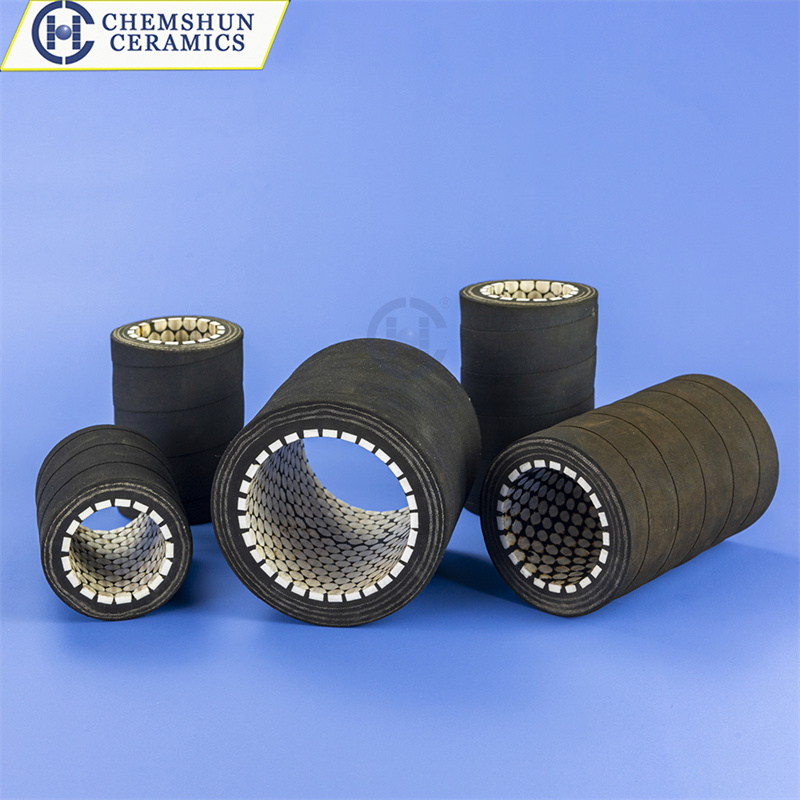

Product detail pictures:

Related Product Guide:

We always think and practice corresponding to the change of circumstance, and grow up. We purpose at the achievement of a richer mind and body as well as the living for Professional China Aluminum Oxide Ceramic - 99.7% Alumina Wafer Polish Plate – Chemshun , The product will supply to all over the world, such as: Peru, Islamabad, Uruguay, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The products to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

Write your message here and send it to us