Reasonable price Ceramic Sleeve - 99.7% Alumina Wafer Polish Plate – Chemshun

Reasonable price Ceramic Sleeve - 99.7% Alumina Wafer Polish Plate – Chemshun Detail:

Application

As the Alumina ceramic wafer polishing and sapphire lapping disks used in the semi-conductive, diamond polishing etc.

Process: All types of Polishing and lapping process, such as CMP chemical mechanical polishing, Mechanical Polishing, Precision Polishing.

Feature

High purity and chemical durability

High Mechanical Strength and Hardness

High Corrosion Resistance

High Voltage Resistance

High Temperature Resistant Up to 1700ºC

Extremely Abrasion Resistance Performance

Excellent Insulation Performance

All type of Size 180,360, 450, 600mm etc

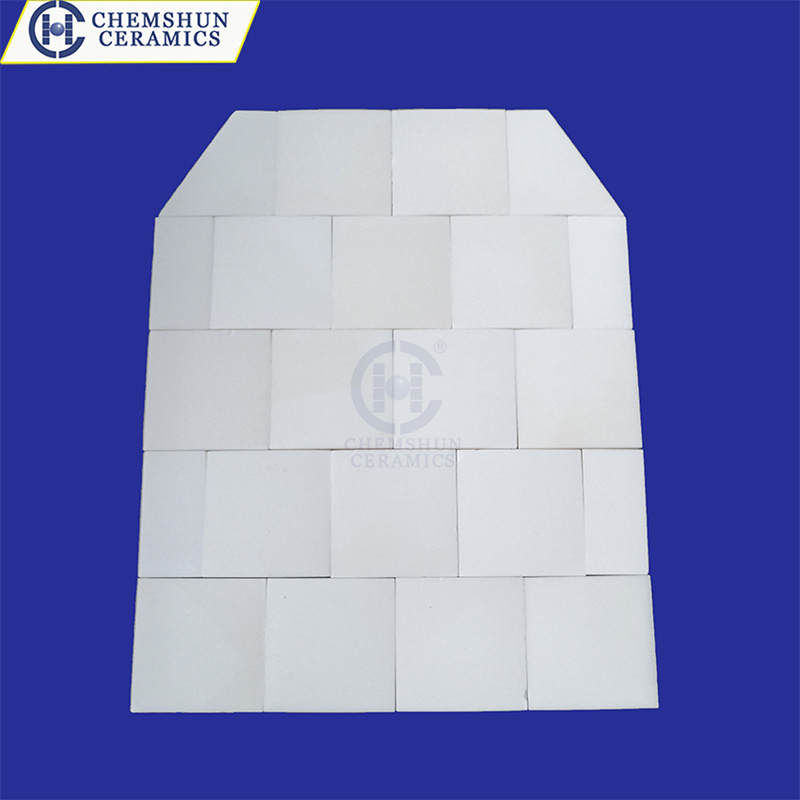

| Product name | 99.7 high purity Alumina ceramic Polishing Lapping Discs |

| Material | 99.7% alumina |

| Normal Size | D180, 360, 450, 600mm, customized size accepted. |

| Color | Ivory |

| Application | Wafer and Sapphire CMP process in semi-conductive industry |

| Min.Order | 1Pic |

Chemical / physical Information

| Unit | 99.7 Alumina Ceramics | ||

| General Properties | Al2O3 content | wt% | 99.7-99.9 |

| Density | gm/cc | 3.94-3.97 | |

| Color | - | Ivory | |

| Water absorption | % | 0 | |

| Mechanical Properties | Flexural Strength(MOR) 20 ºC | Mpa(psix10^3) | 440-550 |

| Elastic Modulus 20ºC | GPa (psix10^6) | 375 | |

| Vickers Hardness | Gpa(kg/mm2) R45N | >=17 | |

| Bending Strength | Gpa | 390 | |

| Tensile Strength 25ºC | MPa(psix10^3) | 248 | |

| Fracture Toughness (K I c) | Mpa* m^1/2 | 4-5 | |

| Thermal Properities | Thermal conductivity(20ºC) | W/mk | 30 |

| Coefficient of Thermal expansion(25-1000ºC) | 1x 10^-6/ºC | 7.6 | |

| Thermal Shock Resistance | ºC | 200 | |

| Maximum use temperature | ºC | 1700 | |

| Electrical Properities | Dielectric Strength (1MHz) | ac-kv/mm(ac v/mil) | 8.7 |

| Dielectric Constant(1 MHz) | 25ºC | 9.7 | |

| Volume Resistivity | ohm-cm (25ºC) | >10^14 | |

| ohm-cm (500ºC) | 2×10^12 | ||

| ohm-cm (1000ºC) | 2×10^7 |

Service

We accept custom orders.

If you want to know more product information, please feel free contact us and we’ll afford you the most suitable product and best service!

Product Tags

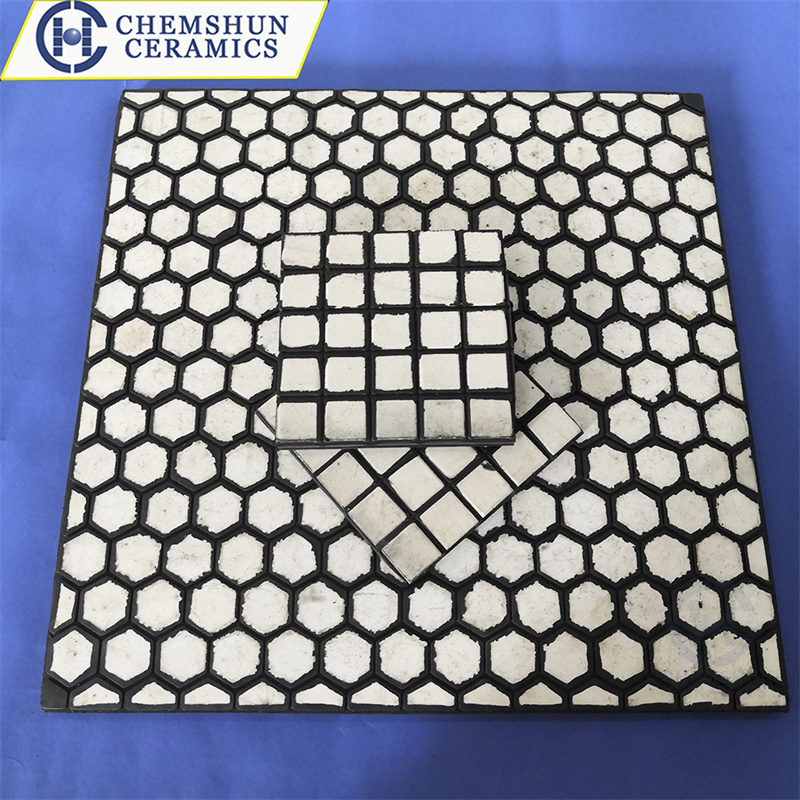

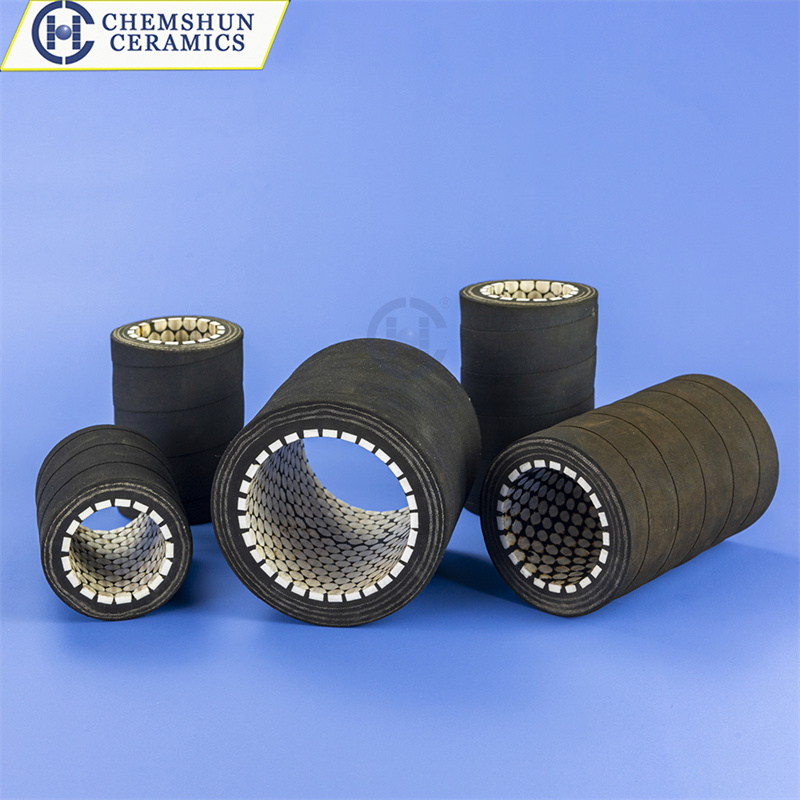

Product detail pictures:

Related Product Guide:

Sticking to the principle of "Super High-quality, Satisfactory service" ,We are striving to generally be a very good business partner of you for Reasonable price Ceramic Sleeve - 99.7% Alumina Wafer Polish Plate – Chemshun , The product will supply to all over the world, such as: Peru, Lithuania, Toronto, The credibility is the priority, and the service is the vitality. We promise we have the ability to provide excellent quality and reasonable price products for customers. With us, your safety is guaranteed.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!

Write your message here and send it to us