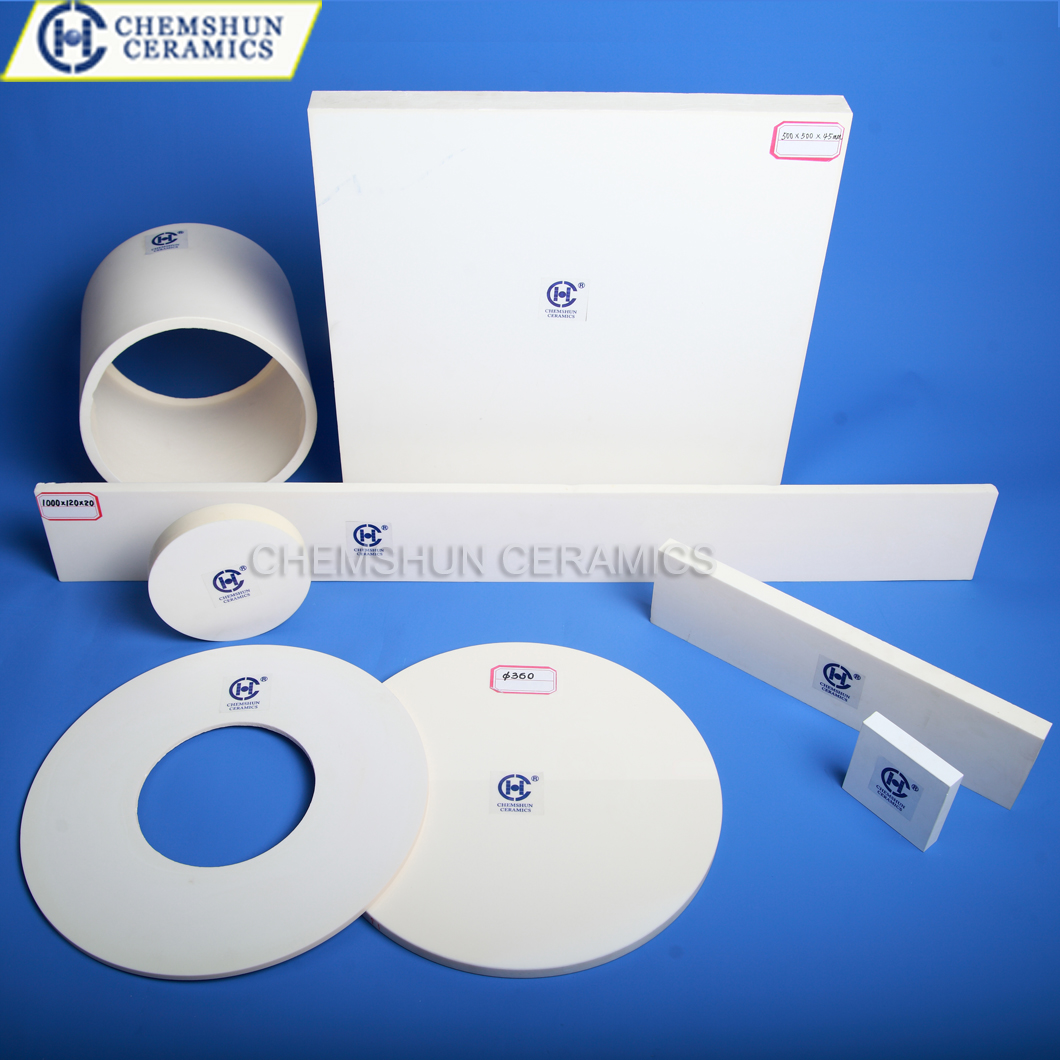

99.7% Advanced Alumina Ceramics

High purity Alumina Ceramics(Al2O3:>99.7%)

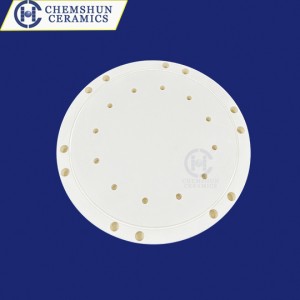

- Alumina Wafer Polishing Plate / Turn Table

-Large Size High Purity Alumina Baseboard for LCD Manufacturing Equipment

Material:

High Purity Alumina Al2O3:>99.7%

Application:

Semiconductor, petroleum, chemical, photovoltaic, LCD etc industries,as mechanical parts, electronic parts, microwave induction disk, insulation parts. Such as manufacturing semiconductor devices, vacuum equipment, liquid crystal manufacturing equipment and other components. For example the large size of high-purity alumina ceramic Wafer Polishing Plate / Turn Table is an important component of CMP in chemical mechanical polishing, the Alumina Baseboard for LCD.

Features:

High-purity Al2O3 99.7% -99.9%

High Mechanical Strength

High Wear Resistance

High Electrical Insulation

High chemical durability

Good Heat and Corrosion Resistance

Manufacturer Advantage:

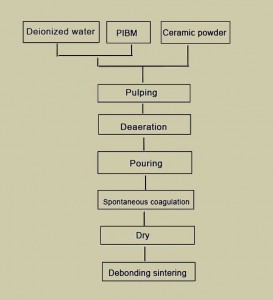

We have independent intellectual property of PIBM Spontaneous Solidification system ,Professionally produce high-quality fine ceramics components.

The new technology break through the deformation and cracking problems of large-sized ceramic wet blanks in the preparation process, and the product performance is significantly optimized for the large-sized ceramic parts prepared by traditional methods.

Chemshun Ceramics’ alumina ceramics sapphire lapping wafer polishing is shaped as PIBM producing process. Its an internaltional advanced technology. PIBM sucessful solve the key problem of crack and deformation of large size alumina ceramics.PIBM technology will open another window of fine ceramics. We not only produce the high quality alumina ceramic wafer polishing plate, but also other series of large size high purity alumina ceramics such as 1200x500x20mm ceramic substrates for LCD manufacturing equipment, semiconductor delviery tracks, vacuum parts, general mechanical parts, bulletproof ceramics.

Product shape and size

1.Alumina Wafer Polishing Plate / Turn Table. Disc, ring size below 850mm, thickness 45mm.

2.Alumina Baseboard for LCD as Support receptors/Carrier Plate. Shape as Long board, long bar, square board, thin board size below 1500*600mm , such as : 1200x500x20, 1400x900x30 etc.

3.Guide rails below 1000 * 45 * 45mm.

4.Empty tubes, cylinders, electric vacuum tubes, etc. With size below 300 ~ 600 × L500mm.

5.Customized products with various shape parts are accepted.

Main Parameter : (Chemical / physical):

|

Property |

Item | Unit |

Chemshun 99.7% Alumina Ceramics |

|

General Properties |

Main component | wt% |

99.7-99.9 |

| Density | gm/cc |

3.94-3.97 |

|

| Color | - |

Ivory |

|

| Water absorption | % |

0 |

|

|

Mechanical Properties |

Flexural Strength(MOR) 20 ℃ | Mpa(psix10^3) |

440-550 |

| Elastic Modulus 20℃ | GPa (psix10^6) |

375 |

|

| Vickers Hardness | Gpa(kg/mm2) R45N |

>=17 |

|

| Bending Strength | Gpa |

390 |

|

| Tensile Strength 25℃ | MPa(psix10^3) |

248 |

|

| Fracture Toughness (K I c) | Mpa* m^1/2 |

4-5 |

|

|

Thermal Properities |

Thermal conductivity(20℃) | W/mk |

30 |

| Coefficient of Thermal expansion(25-1000℃) | 1x 10^-6/℃ |

7.6 |

|

| Thermal Shock Resistance | ℃(∆ Tc) |

200 |

|

| Maximum use temperature | ℃ |

1700 |

|

|

Electrical Properities |

Dielectric Strength (1MHz) | ac-kv/mm(ac v/mil) |

8.7 |

| Dielectric Constant(1 MHz) | 25℃ |

9.7 |

|

| Volume Resistivity | ohm-cm (25℃) |

>10^14 |

|

| ohm-cm (500℃) |

2×10^12 |

||

| ohm-cm (1000℃) |

2×10^7 |

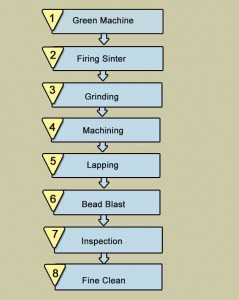

Molding Process Ceramic finishing process

Quality Assurance:

Each Batch products is inspected in the factory lab and the National Inspection Center.