Alumina Ceramic Grinding Balls for Mining

Alumina ceramic mining ceramic grinding media characters

- High hardness with Moh’s hardness 8~9 grade

- High abrasion and Lower abrasion loss

- Widely application for grinding materials

- High density with stronger impact resistance

- Chemical resistance for acidic medium application

Chemshun grinding ball size

| Size (mm) | D1-3 | D6/8/10/13/16/20/25 | D30/40 | D50/60 |

| Tolerance (±mm) | 0.5 | 1 | 2 | 3 |

Technical data of ceramic grinding media

| Item | Alumina Content |

Mohs hardness | Abrasion loss (24hours) |

Density (g/cm3) |

Water absorption |

| 92% ball | 92% | 9 | <0.01% | 3.6 | <0.01% |

| 95% ball | 95% | 9 | <0.01% | 3.74 | <0.01% |

| 68% ball | 68% | 7-8 | <0.03% | 3 | <0.02% |

| Producing way :cool-isostatic pressing , or by rolling | |||||

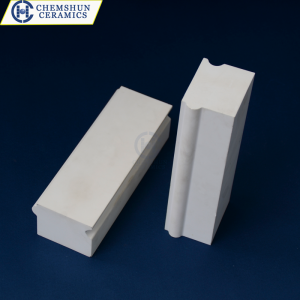

Ceramic grinding media for mining industry series

| Item | Main | Diameter | Density | Application Suggestion |

| (mm) | (g/cm3) | |||

| CS-26 | Al2O3,SiO2 | 0.5~20 | 2.6~2.8 | It’s suitable for the stirred mill such as Metso’s SMD and fine milling process of soft materials with low slurry density. |

| CS-32 | Al2O3, SiO2 ZrO2 |

0.5~20 | 3.2~3.3 | It’s suitable for the stirred mill such as Metso’s SMD and milling the hard minerals. |

| CS-36 | Al2O3 | 0.4~25 | 3.5~3.75 | It suitable for the Nano-size material grinding. |

| CS-38 | Al2O3, ZrO2 | 0.4~20 | 3.8~3.9 | It’s suitable for the stirred mill such as Metso’s SMD and milling the hard minerals. |

| CS-40 | ZrO2,SiO2 | 0.4~5.0 | 4.0~4.2 | It’s suited for high speed milling of mineral ores and similar hard materials. |

| CS-52 | ZrO2,Al2O3 | 0.4~5.0 | 5.1-5.3 | It suitable for the hard materials’s superfine mills with high speed (up to 14m/S) and high energy input. For example: Outotec’s HIG mill. Flsmidth VXP. |

| CS-60 | ZrO2,Y2O3 | 0.2~40 | 5.95~6.05 | 1.Chemical materials,paint,printing,ink,pigment. 2.Advanced ceramics pastes or powder. 3.Electronic pastes: gold platinum, silver,cuprum, nickel. 4.Food stuff,pharmaceuticals,cosmetics. |

| CS-62 | ZrO2,CeO2 | 0.6~4.0 | 6.1~6.2 |

Product Tags

Write your message here and send it to us