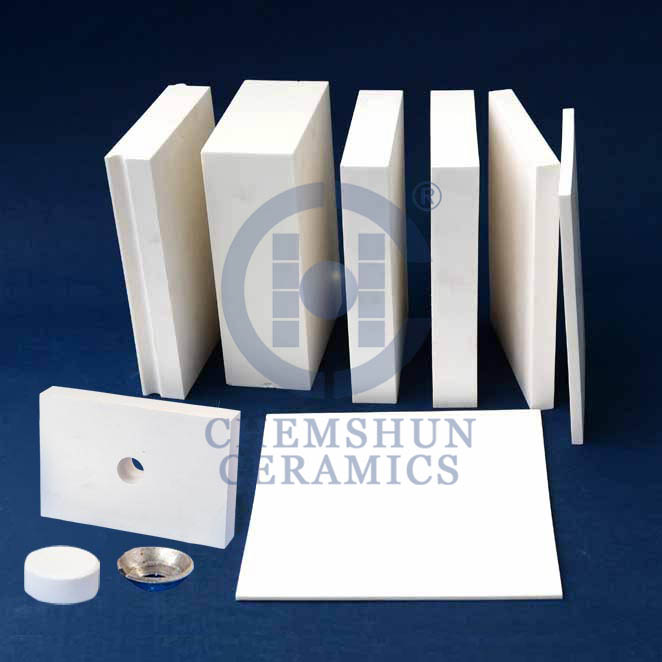

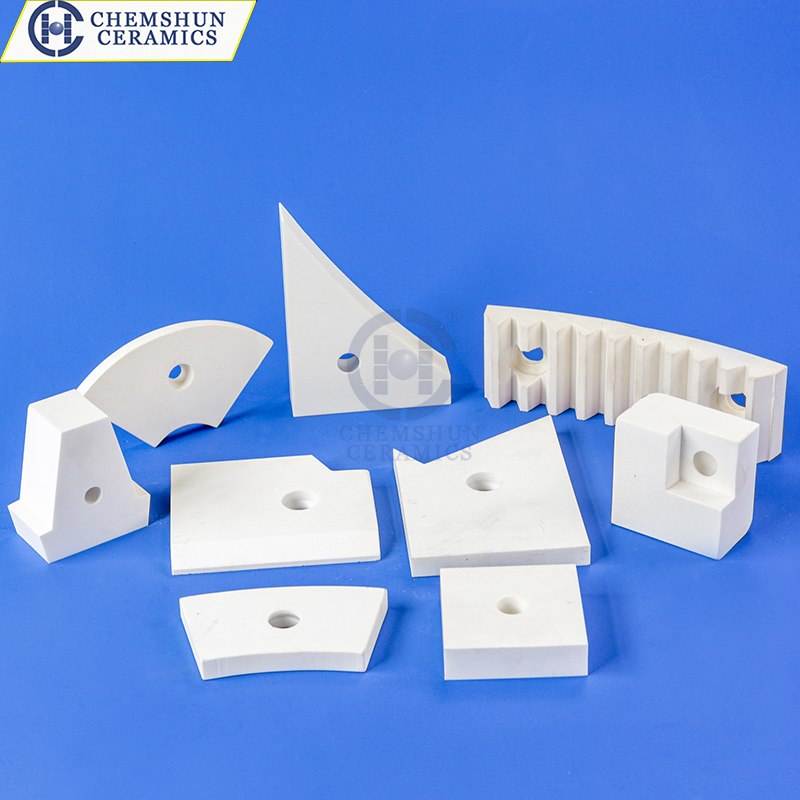

Alumina wear-resistant ceramic lining tile, also known as: wear-resistant ceramic lining tile, high aluminum lining, wear-resistant lining tile, alumina lining, alumina ceramic tile pipeline wear-resistant lining.

Features: With wear resistance, impact resistance, corrosion resistance, high temperature resistance, convenient construction and other characteristics, is electric power, metallurgy, coal, petroleum, cement, chemical, machinery and other materials (such as ash slag, coal powder, fine ore powder, tailings, cement, etc.) conveying equipment surface wear-resistant ideal material, in high temperature corrosion, high temperature wear or high temperature corrosion under the occasion of very safe and reliable use, Its life is ten to twenty times higher than that of cast stone, wear-resistant alloy cast steel, steel plastic, steel rubber and other materials.

Application industry:

Steel industry

Feed system: bucket turbine disc, hopper, bin, belt machine skirt plate, trolley tee bucket, receiving hopper.

Batching system: mixing bin, primary mixing cylinder, secondary mixing cylinder, mixing disc, mixing drum scraper, making ball disc.

Sintering system: vibrating screen beneficiation hopper, raw material transport chute, cyclone dust collector and pipeline, fan impeller.

Cement industry

Limestone crushing system and raw fuel prehomogenization system: chute, hopper, belt roller.

Raw material grinding system: separator guide blade, separator cone, vertical grinding to cyclone bobbin, cyclone barrel, fuel mill (steel ball mill), separator shell, inner cone, pulverized coal pipeline.

Fuel mill (steel ball mill) : separator shell, inner cone, pulverized coal pipe, pulverized coal pipe.

Port industry

Berth fixed funnel, bucket engine fixed funnel, belt conveyor transfer station fixed funnel, ship unloader hopper.

Smelting industry

Feeding system: head chute, silo (middle silo, tail silo), vibrating screen material trough, coke bucket, metering bucket.

Batching system: batching bucket, primary (secondary) mixer.

Roasting system: single bin pump calcine tube, batching hopper, ash hopper, intermediate bin hopper.

Chemical industry

Feeding system: hopper, bin.

Dust removal system: dust removal pipe, elbow, fan shell and impeller, cyclone.

Coal industry

Coal transport system: chute, hopper, bin.

Coal washing system: pressure cyclone, no pressure three product heavy media cyclone, no pressure four product heavy media cyclone, concentrated cyclone group.

Feed system: pipe, elbow, pipe, hopper, bin, distribution port.

Mining industry

Feeding system: hopper bin.

Installation: divided into welding and adhesive two, according to the construction environment.

Post time: Dec-21-2022