Mining industry every day in mining, crushing, screening ore and other operations, it is a typical heavy wear industry, mining industry equipment easy to wear, and the need for frequent maintenance and replacement, which is a major problem plaguing many mining industry companies. The installation of ceramic rubber composite liner is a common anti-wear scheme for mining equipment.

In the case of cement raw material limestone mines, limestone needs to be mined from the mountains, then broken into 100mm diameter stones in the mining industry’s machines, and then transferred to the cement plant through a conveyor belt, which will pass through multiple transfer stations. The transfer station needs to transport thousands of tons of ore every day, and the transported stone is very hard, the edge of the stone is also very sharp, in order to play the role of crushing and mixing again, the stone from the conveyor belt into the transfer station hopper will have a higher height, which leads to the transfer station hopper, the chute will be subjected to strong impact and wear.

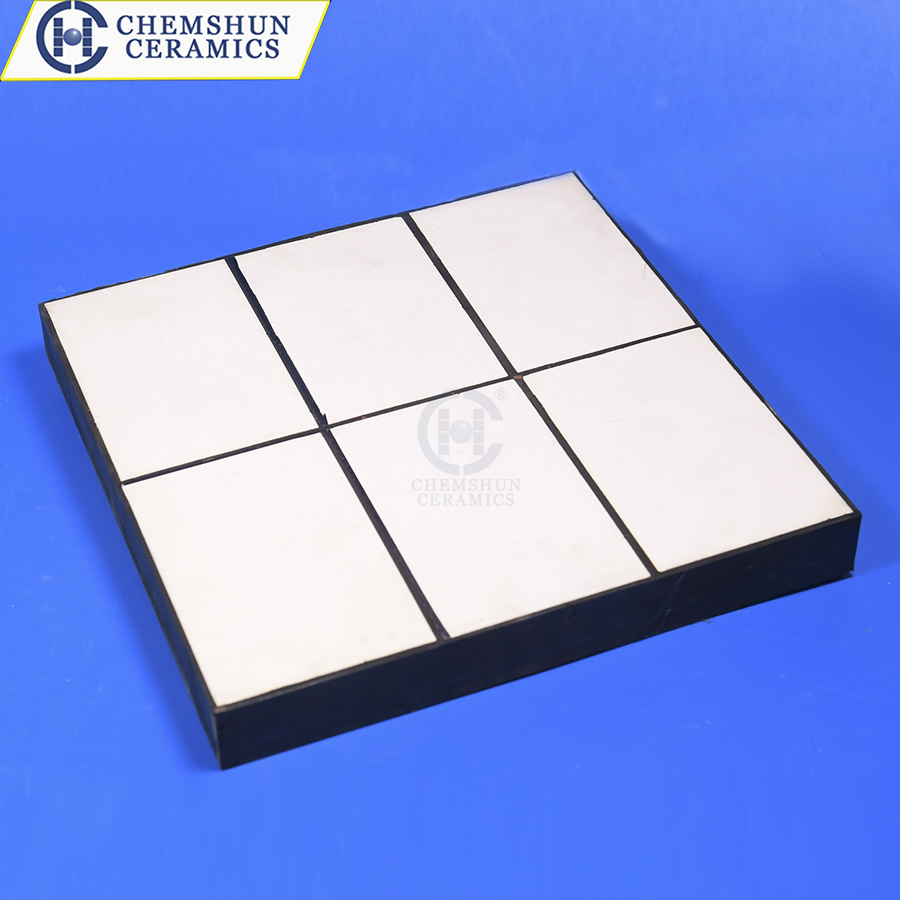

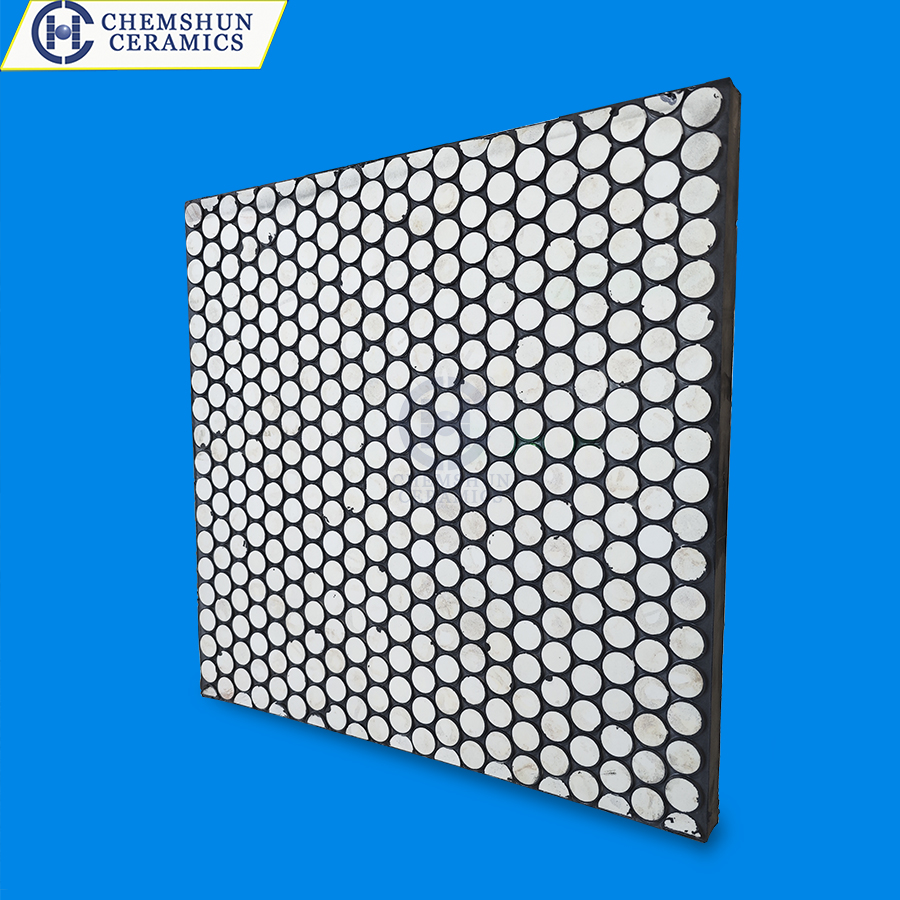

The hardness of alumina wear-resistant ceramics can reach more than HRA85, strong wear-resistant ability, rubber can resist impact, seismic noise reduction, connection fixed ceramic lining plate, the combination of the two forms ceramic rubber composite lining plate, which is very suitable for mining conditions.

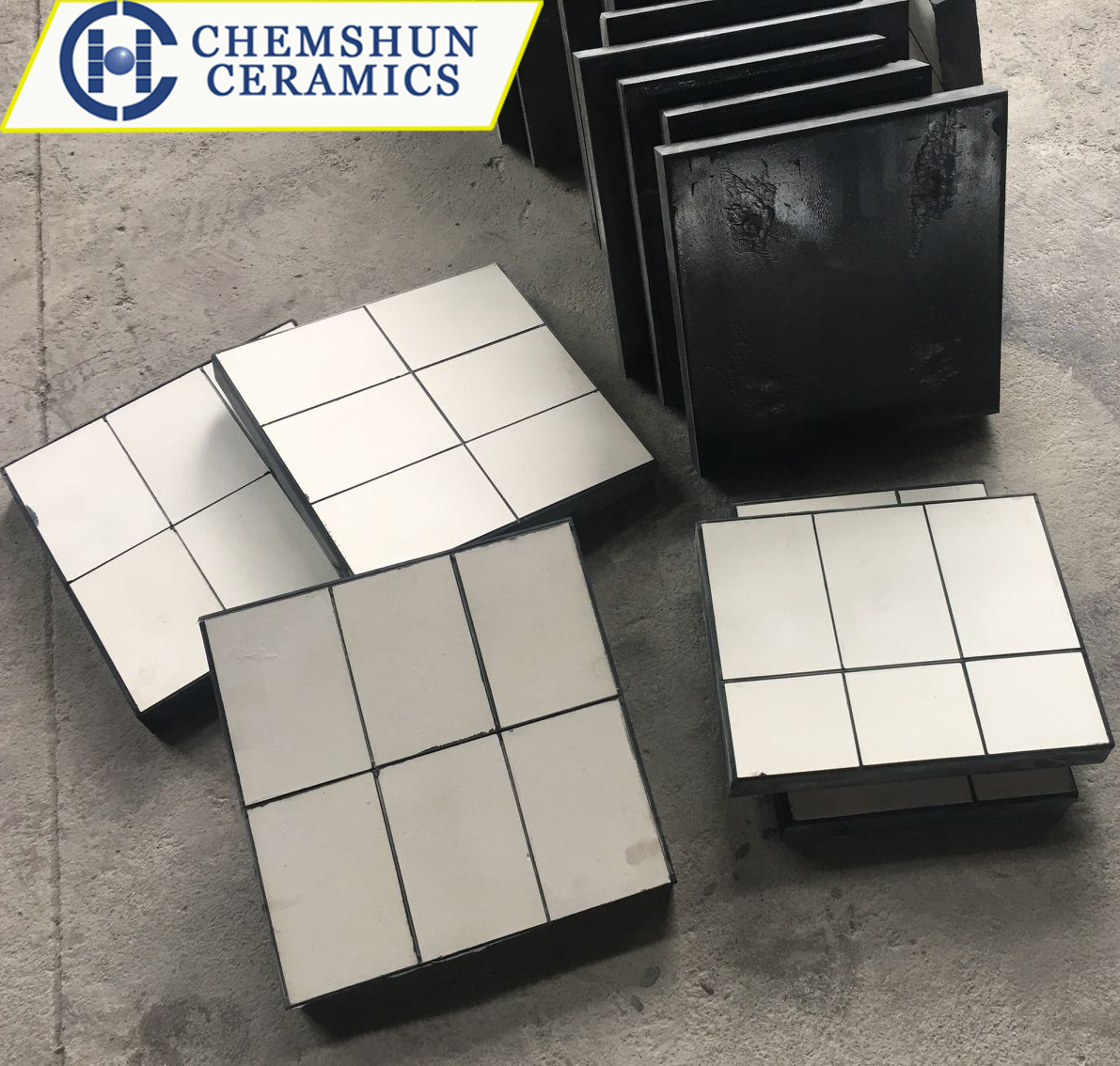

According to the drop point of the ore, the fall height and the composition of the ore itself, the transfer station hopper chute can choose different ceramics. Usually places with large impact need to use high hardness, impact resistant wear-resistant ceramics, such as ZTA ceramics, 99 alumina ceramics, and these places can use thickened ceramics, with thick rubber layer, and then fixed installation with countersunk bolts. Other places with less impact wear can use relatively cheap ceramics, and the rubber layer can be thinner.

In addition to the chute, hopper, other heavy wear, strong impact equipment parts can use rubber ceramic composite plate, and you can choose different ceramics according to different working conditions, to ensure anti-wear ability while saving costs.

Post time: Apr-09-2024