Alumina ceramic tile lining is a modern ceramic product with excellent corrosion resistance and wear resistance. The hardness of abrasion resistant ceramics is very high, and it is currently the wear resistant material second only to diamond. The density of alumina ceramic tile lining is small, and the weight is only half of that of metal. It is one of the best choices for the surface material of wear-resistant and corrosion-resistant work parts. Alumina tiles are widely used in thermal power, steel, smelting, machinery, coal, mining, chemical, cement, port and wharf enterprises such as coal conveying, material conveying system, pulverizing system, ash discharge, dust removal system, etc. In terms of mechanical equipment, because of the wide range of applications of ceramic tile liner, we often face the purchase of alumina tile liner in daily life, so how should we quickly distinguish inferior ceramic tile liner ?

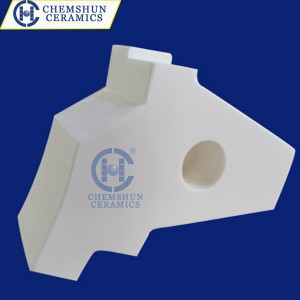

1. The promising alumina ceramic lining has a flat surface, no black spots, smooth and not rough, and uniform color. In addition to vulcanization, the wear-resistant ceramic lining will be pasted on a background paper for the convenience of construction, and the seams will continue to form a straight line.

2. Density measurement, alumina content can be calculated by density measurement

3. To do anti-wear test, use a sandblasting machine to measure the wear within 60 minutes at a pressure of 4.0kg/cm3, a distance of 50mm, and a spray angle of 45 degrees.

Post time: Mar-21-2023