Wear-resistant ceramic pipe is made of alumina ceramic, ceramic special adhesive, and steel pipe combination. Alumina ceramic as a protective layer inside the steel pipe, with high anti-wear ability. Wear-resistant ceramic pipe service life is several times higher than the general wear-resistant pipe, widely used in lithium battery, steel, cement, coal transmission pipeline.

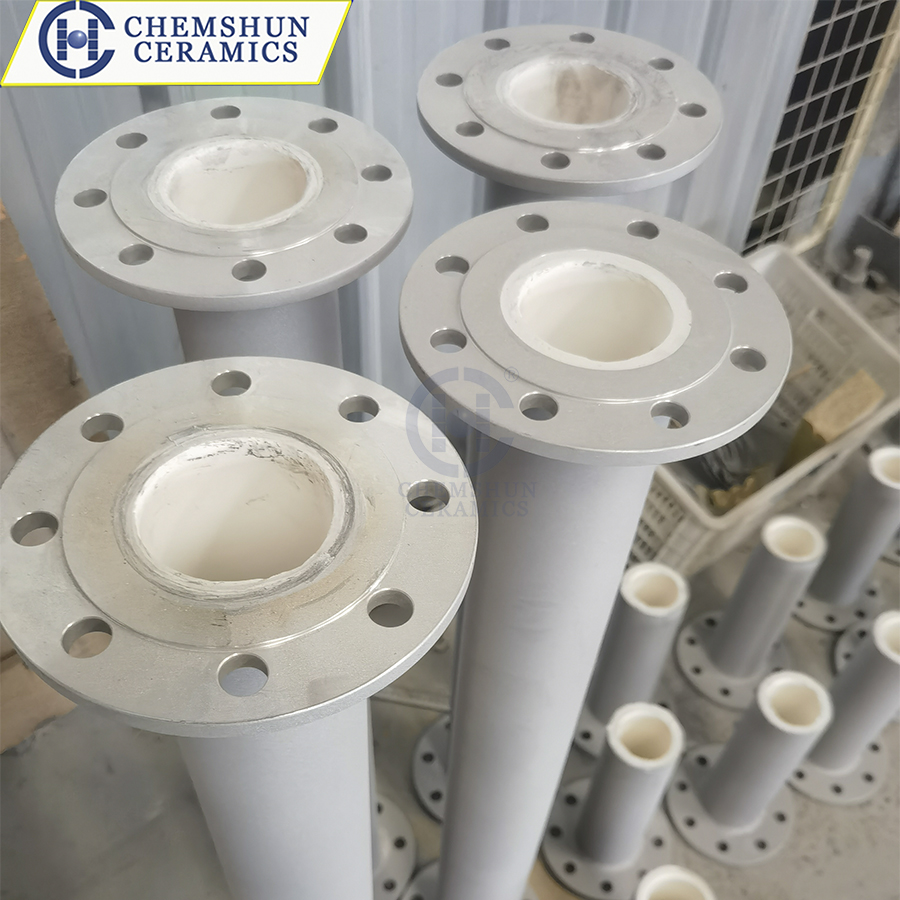

There are several different ceramic lining construction processes for wear-resistant ceramic pipes. One is lined with alumina ceramic tube, ceramic tube by isostatic pressing after burning molding, segment installed in the steel pipe, the inner wall is smooth, fewer steps, less gaps, can reduce the material conveying resistance, suitable for pneumatic conveying industry, such as lithium battery, thermal power industry.

There is also a ceramic lining tile mat, the use of ceramic pieces or ceramic lining tiles, pasted in the pipeline, this construction is more complex, the need for professional construction technology.

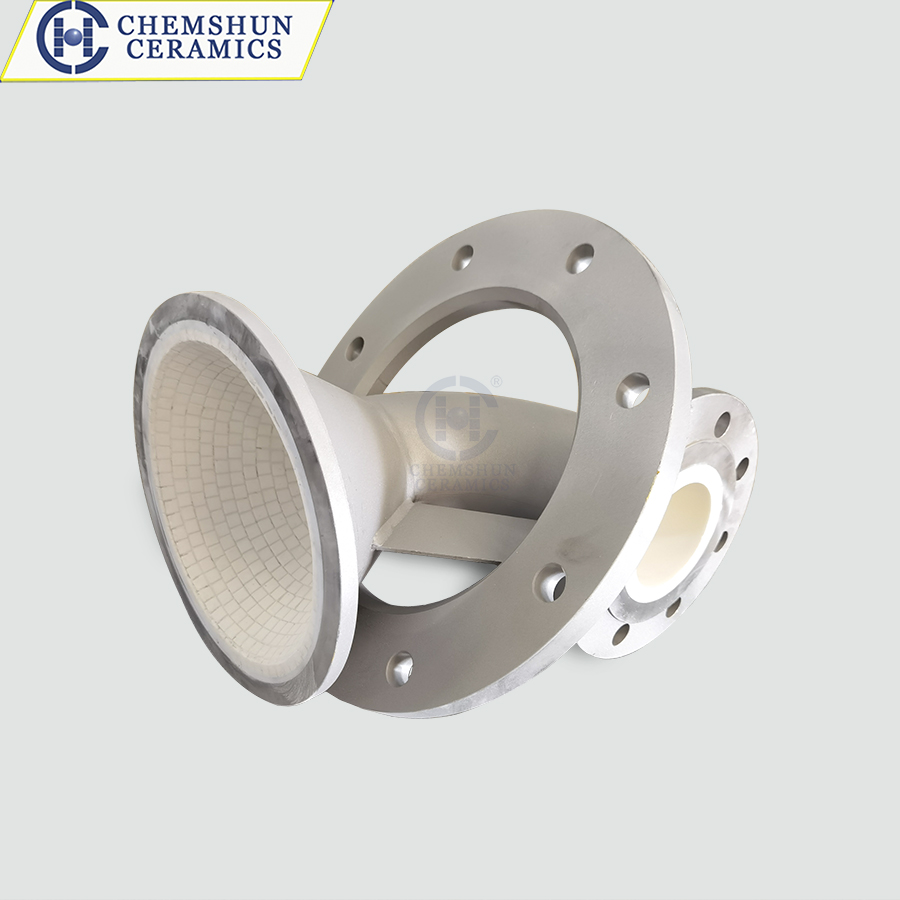

There is also a welded ceramic pipe, the use of ceramic lining plate with holes, the ceramic special glue on the ceramic lining plate, and then the iron sheet through the small hole welded in the steel pipe, and finally sealed the ceramic cover, to protect the solder joint. The welded ceramic pipe is suitable for conveying conditions with strong impact, and the double fixed process can resist the impact force and friction of the material. Therefore, welded ceramic pipes are suitable for making chute and bin hopper.

Chemshun Ceramics can provide wear-resistant ceramic tubes suitable for various working conditions, can choose the appropriate ceramic lining installation method according to customer needs, welcome to consult: office@chemshun.com

Post time: Jul-24-2023