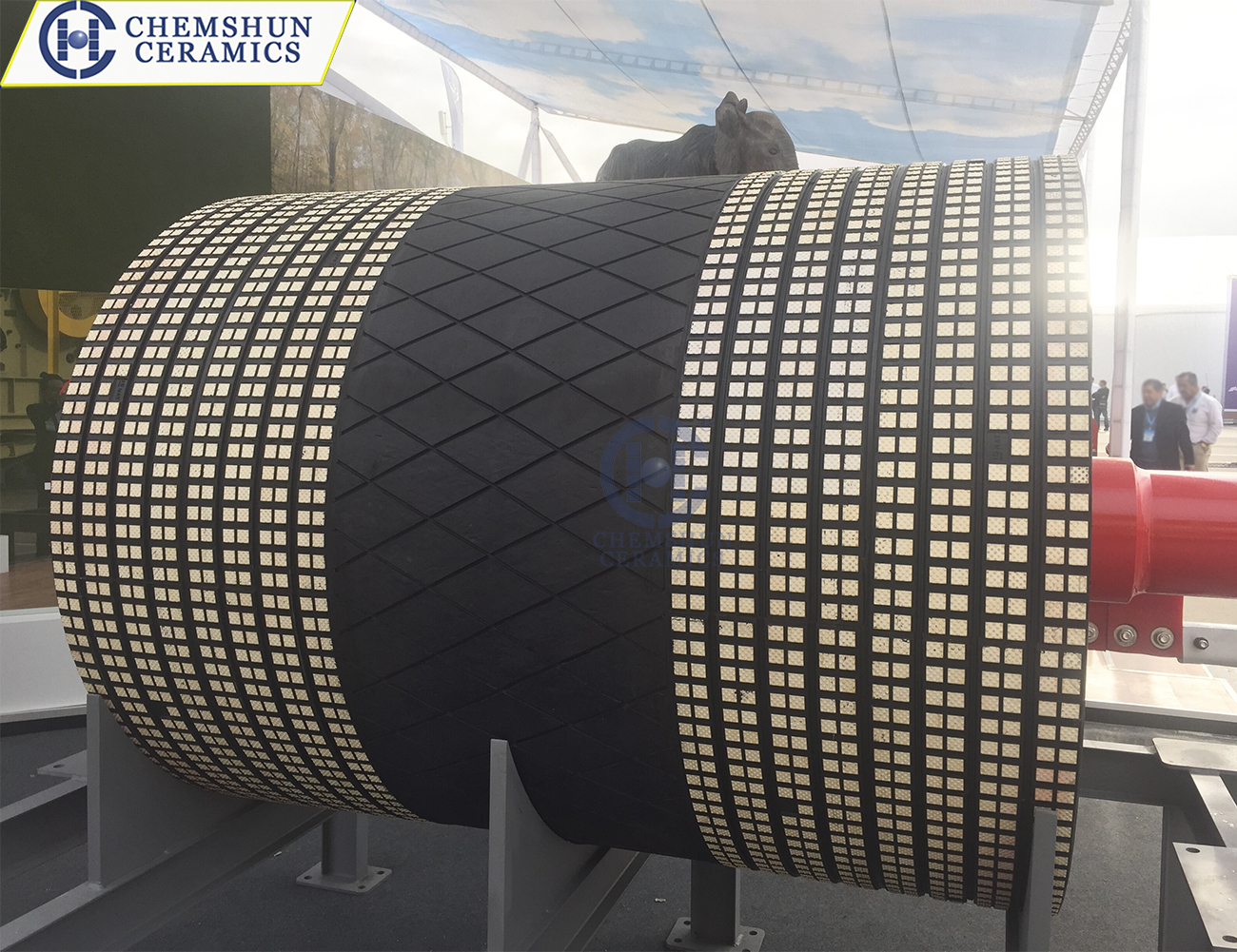

The wear-resistant ceramic pulley lagging product is produced through a hot vulcanization process, where the ceramic tiles with surface protrusions are firmly bonded to special rubber. This product can significantly extend the service life of the drum and effectively prevent the conveyor belt from slipping and deviating.

1.Wear-resistant ceramics with bumps on the surface

The wear-resistant ceramic pulley lagging is made of high-hardness alumina ceramic with bumps on the surface. The surface of this ceramic is designed with a regular distribution of bumps, which can increase the friction coefficient at the contact surface with the conveying belt, preventing slipping. At the same time, the gaps between the bumps help to discharge water and fine materials, reducing contamination of the friction surface.

2. Hot Vulcanization Process

The wear-resistant ceramic pulley lagging is carried out using the hot vulcanization process. First, the surface of the metal drum is treated with sandblasting cleaning to reach the Sa2.5 standard; then, special rubber with high wear resistance and tear resistance is evenly adhered to the surface of the drum, and ceramic pieces with bumps are arranged on the rubber layer according to the design requirements. Then, it is sent to the vulcanization equipment and vulcanized under high temperature and high pressure conditions. The high temperature and high pressure cause the rubber to undergo a vulcanization cross-linking reaction, and the liquid rubber flows and fully fills the gaps of the ceramic protrusions and the micro-pores on the metal surface. After vulcanization, the rubber solidifies, forming a firm and inseparable whole with the ceramic pieces, the rubber layer, and the metal drum.

3.Application of Wear-resistant Ceramic Pulley Lagging

Wear-resistant ceramic pulley lagging possess the characteristics of high wear resistance, long service life, anti-slip property, and low maintenance cost. They are widely used in industrial fields that require high wear resistance and anti-slip properties, such as the transportation of ores and coal in mining operations, the loading and unloading of bulk cargo at ports and docks, the transportation of coal in thermal power plants, the transportation of raw materials, clinker, and cement in cement plants, the transportation of ores, sintered ore, and coke in steel mills, and other long-distance, high-inclination belt conveyor systems with heavy loads, high wear, humidity, or slippery conditions.

Post time: Aug-18-2025