Many industries will be applied to dust removal equipment, such as smelting plants, steel plant dust removal; Metallurgy, mining industry large air volume flue gas purification dust removal; Dust purification in chemical and machinery industries, etc.The dust removal pipe used by these dust removal equipment is often worn, the wear of the elbow part is light, there is ash accumulation phenomenon, the main wear is in the upper part of the pipe.Wear will cause air leakage in the system, affect the control effect of dust source, destroy the function of dust removal system, and even cause system paralysis. For elevated dust removal pipeline, wear will make the strength and stiffness of elbow decline sharply, bringing unsafe risks.

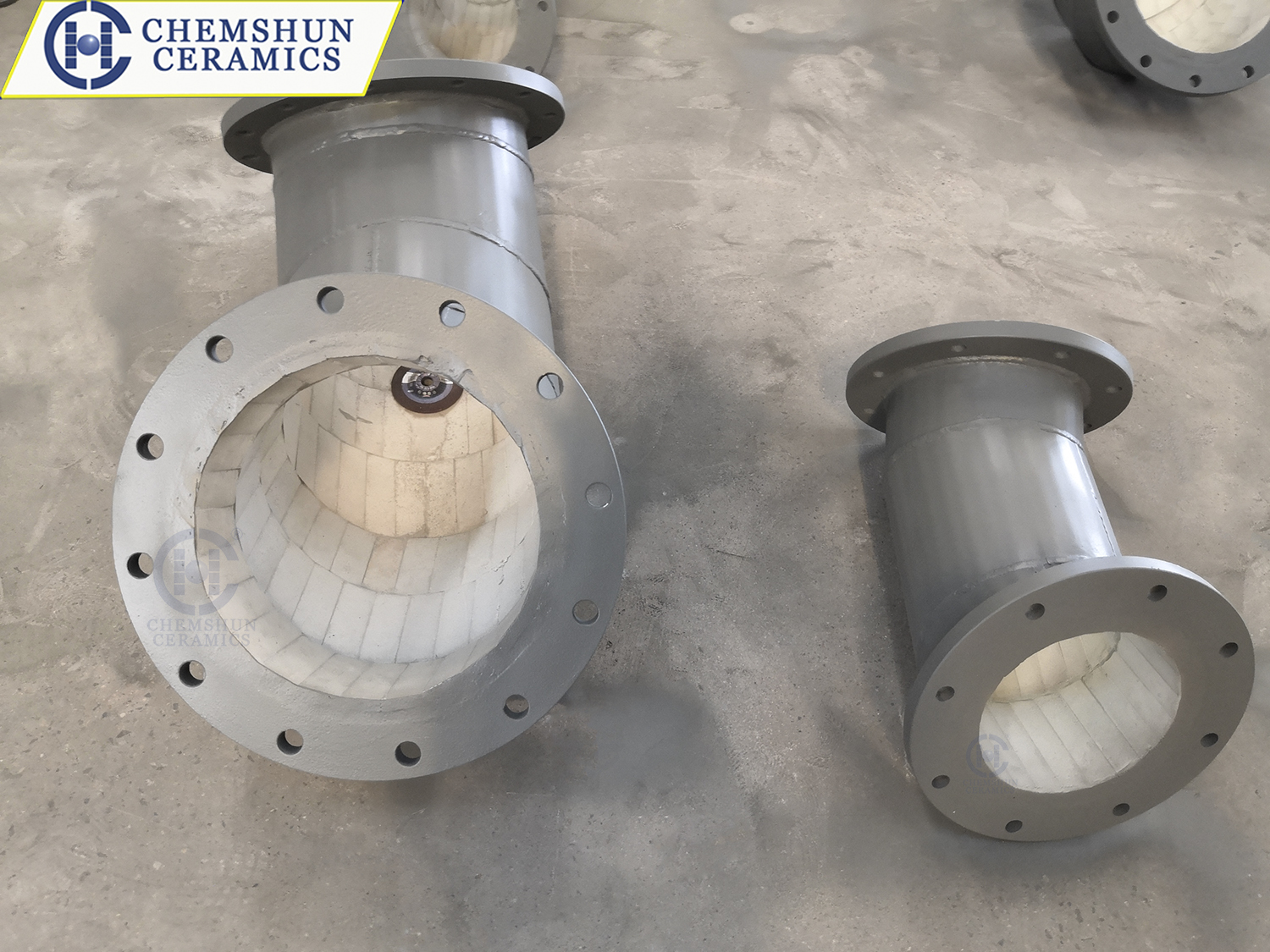

Therefore, we must pay great attention to the damage of dust removal pipeline wear and prevent it in time. The wear of pipe elbow is caused by the impact of solid dust particles on the wall surface. Therefore, it is necessary to take anti-wear measures on the inner wall of the pipeline. We suggest the use of alumina wear-resistant ceramic lining in the pipeline, the wear-resistant ceramic is very excellent, can effectively protect the inner wall of the pipeline from wear, and the surface is smooth, will not appear the phenomenon of blocking material. This can increase the service life of the pipeline by at least ten times. Wear resistant ceramics can be a good solution to the problem of dust removal pipe wear.

Post time: Oct-10-2022