Wear is an important factor that affects the stable operation of production and determines the life of the workpiece, and reducing wear is the common vision of all walks of life. Want to reduce wear, we need to find the main factors affecting workpiece wear, then what are the main factors affecting wear?

Relative motion speed, contact stress and friction time of abrasive and workpiece: the higher the relative motion speed of abrasive and workpiece, the greater the contact stress, the longer the friction time, the more serious the wear. Without affecting the efficiency of material transportation and production efficiency, it is difficult to reduce wear from this point, so we usually start from several other aspects.

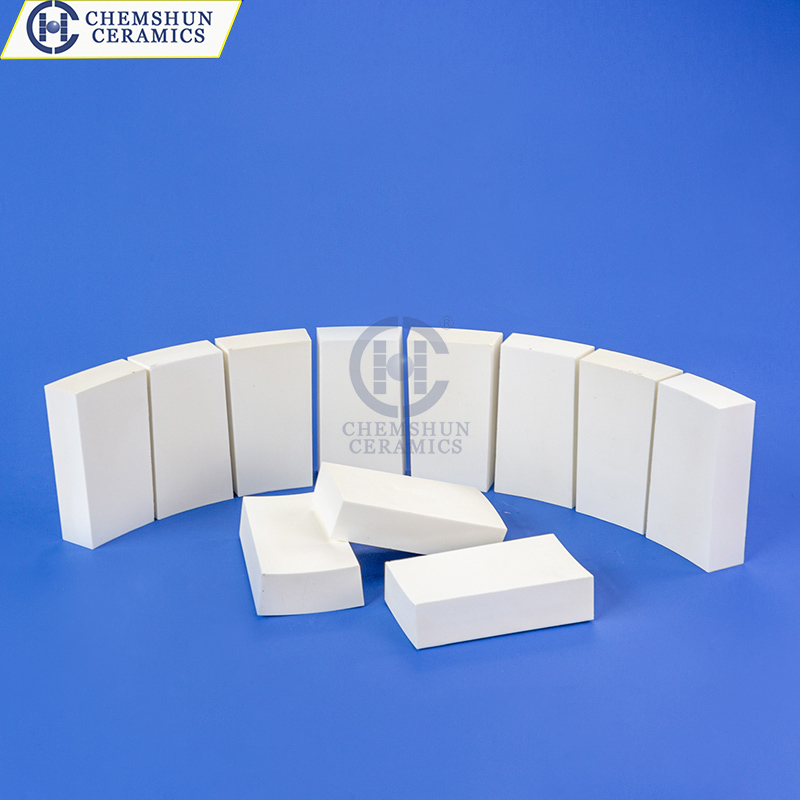

Workpiece material hardness: under the premise of the same material, the higher the hardness of the workpiece material, the smaller the wear, which is an effective entry point to reduce wear. We can change the workpiece material, such as the original cast stone, steel, high manganese steel, alloy and other materials into wear-resistant ceramic material, Chemshun Ceramics special porcelain production of wear-resistant ceramics hardness up to HRA88, second only to diamond, can effectively reduce workpiece wear. Some workpieces should not be directly replaced with wear-resistant ceramic materials, such as pipes, chutes, hoppers, etc., and wear-resistant ceramic pieces can also be pasted on the friction surface as an anti-wear layer to reduce wear.

Workpiece lubrication and surface smoothness: Smooth or effective lubrication of the workpiece surface can reduce friction, thereby reducing workpiece wear. Wear- resistant ceramics have a high surface smoothness, and Chemshun wear-resistant ceramics use a unique formula, so that it has a self-lubricating component, the more smooth the wear, but also reduce wear.

Impact Angle of abrasive: under normal circumstances, the abrasive flow direction is parallel to the surface of the workpiece, that is, the erosion Angle is smaller, and the erosion Angle is large when the wear is serious, so the elbow, baffle and other parts are usually seriously worn. However, the scouring Angle is not easy to change, so we generally improve the wear resistance of the bend to ensure the service life of the entire transport line, and the effective way to improve the wear resistance of the bend and the baffle is to use wear-resistant ceramics.

Working environment and abrasive shape properties: harsh working conditions, such as sudden cooling, humidity, high temperature and other harsh working conditions will also lead to increased wear, and abrasive hardness, sharp edges will also increase wear, but these factors are not easy to change, or the cost of change is too high, so it is usually not used.

There are many factors affecting the wear of the workpiece, but it is easy to change and control it without affecting the production. The use of wear-resistant ceramics and other materials to improve the anti-wear ability of the workpiece itself is an effective solution to reduce wear. We have been engaged in anti-wear work for more than 20 years, and the quality of wear-resistant ceramics has been recognized by peers and praised by customers.

Post time: Jul-11-2023