ZTA Ceramic Plate Sheet

Product Description

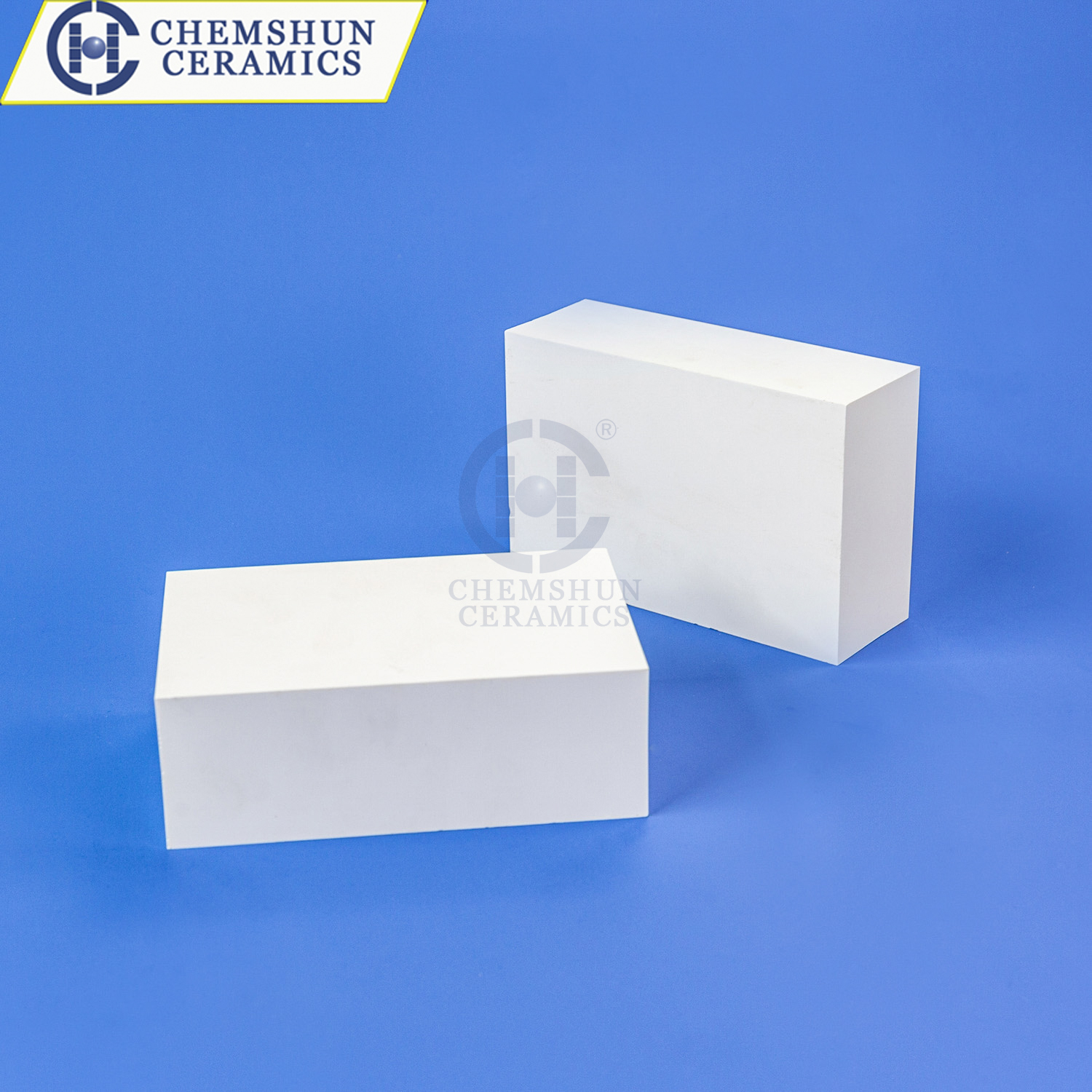

The Zirconia Toughened Alumina Ceramic also named ZTA ceramic, which is white color, is a combination material of the aluminum oxide and 20~25% zirconium oxide. ZTA Ceramics is an new material developed in the recently years.

Chemshun ZTA is a considerable improvement in impact strength and toughness over alumina ceramic. Chemshun ZTA’S wear resistance is 2.5 better times than the alumina ceramic. ZTA offer increased component life and a more cost effective long term solution, it’s very suitable for extreme impact and wear equipment of mining industry. Now the BHP Australia used a lot of the ZTA Ceramic Liners

Shape and Type of ZTA Ceramics

Chemshun ZTA ceramics can be produced into ceramic plain type, arc type, cube, cylinder, hex tile etc.

Special machinery parts are also customized designed with CAD drawings.

In order to better take advantage of ZTA, we usually vulcanize ZTA to rubber and steel and install bolts on the back of the steel.We called the combination as wear ZTA ceramic rubber liner. Customers can easily install the product on site.

Features of ZTA Wear Impact Resistant Ceramics:

Higher Impact Resistant strength than High alumina

Much Lower cost than purity zirconia ceramics

Exceptional wear resistance

High corrosion resistance

High fracture toughness

High temperature stability

Technical Data :

| No. | Item | Data |

| ZTA ceramics property | ||

| 1 | ZrO2 | 20-25% |

| 2 | Al2O3 | 75-80% |

| 3 | Density(g/cm3) | ≥4.2 |

| 4 | Compressive Strength(Mpa) | ≥1500 |

| 5 | Vickers Hardness (HV 10) | ≥1300 |

| 6 | Rockwell hardness (HRA) | ≥90 |

| 7 | Flexural Strength (20ºC, Mpa) | >350 |

| 8 | Elastic Modulus(Gpa) | 320 |

| 9 | Fracture Toughness KIC (Mpa.m1/2) | ≥3.70 |

| Rubber Property | ||

| 10 | Rubber | Natural |

| 11 | Tensile strength (Mpa) | >12 |

| 12 | Tensile Elongation | >400% |

| 13 | Hardness (Shore A) | 55~65 |

| 14 | Bond strength of rubber and ceramics (shear modulus, Mpa) | >3.5 |